Introduction

The engine is the heart of a car, as the car would not be able to make movements without receiving the power or energy that is produced by the engine. To continuously create power that the other parts of the car can use, the engine would need the help of pistons that are installed on top of it or the sides. Together, the components of the piston convert thermal energy into mechanical work and vice versa. The air-fuel combination expands and compresses as it goes up and down inside the cylinder. Because of this, an internal combustion engine must have a piston.

What are these pistons? And how exactly do they help produce energy for the engine? We will find out the answers as we take a deeper look into engine pistons and how they work.

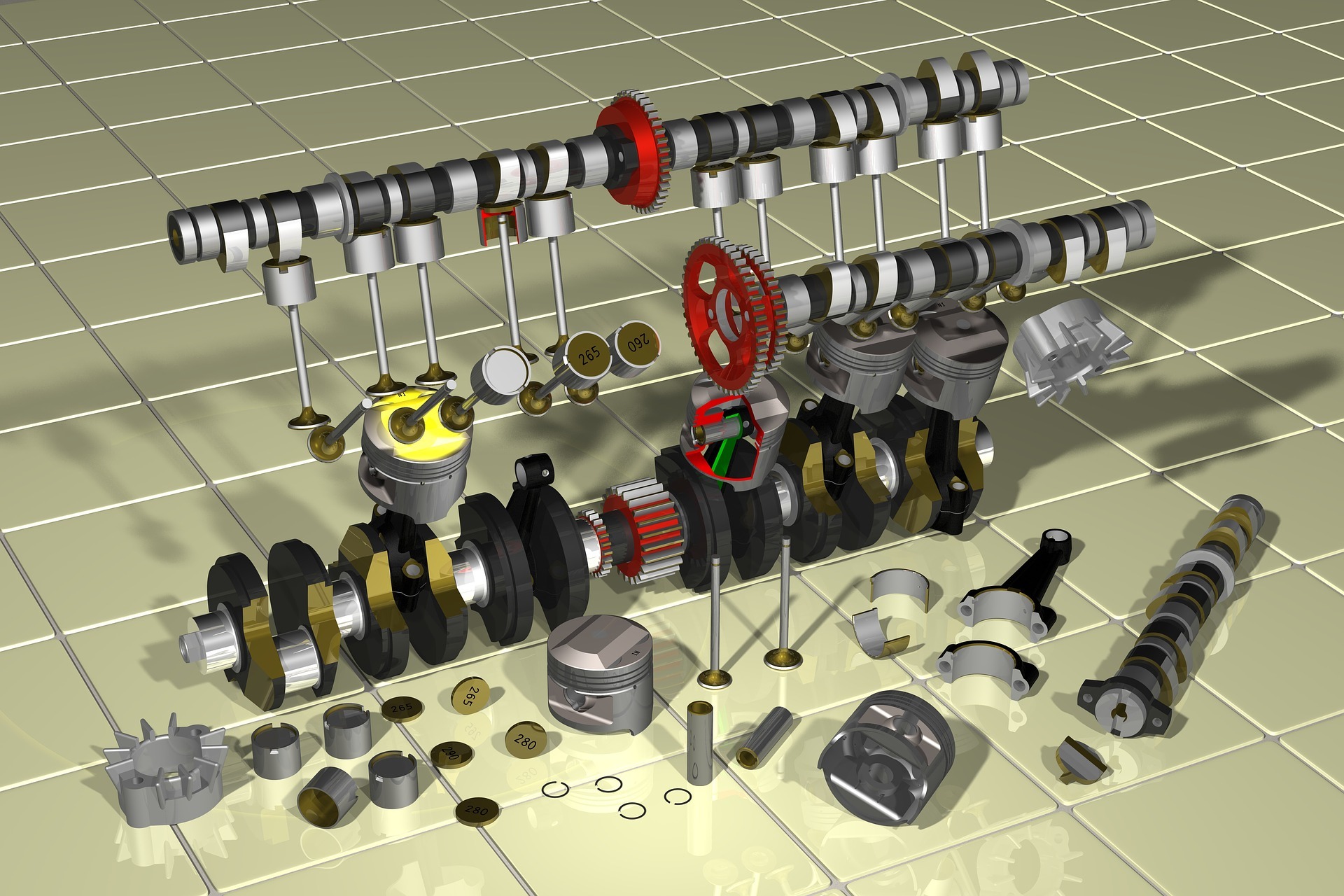

Components of an Engine Piston

Piston head

The upper surface of the piston is sometimes referred to as the crown or dome. It is the area that comes into touch with the combustion gases, which causes it to reach extremely high temperatures. A specific steel alloy, for example, is used in the piston’s construction because it can sustain high temperatures without melting. The piston’s job is to take the pressure, temperature, and other stresses of the expanding gas. The function of the piston head also includes regulating knocking and generating swirl to ensure even combustion. Between the combustion chamber and the lower sections of the piston, the head of the piston serves as a heat barrier. Different types of pistons are available, each suited for a particular kind of engine. The type of engine and necessary performance are only a couple of the numerous variables that affect a piston head’s design.

Piston skirt

A piston skirt is a cylindrical piece of material that is connected to the piston’s spherical part. Cast iron is typically used in construction because of its self-lubricating qualities and ability to withstand wear. The skirt has grooves that allow piston rings to rest correctly. The piston skirt’s job is to move up and down the cylinder. It is made to withstand the side forces generated when the connecting rod’s angle is changed. Piston skirts come in two basic varieties: full skirts and slipper skirts. The solid skirt is another name for the full piston skirt. It has a tubular form and is frequently found in big car engines. While motorcycles and a select few cars frequently have slipper piston skirts. The surfaces on the front and rear of the cylinder wall are all that remain of a portion of the skirt that has been cut away. As a result, the weight is decreased and the contact area between the piston wall and the cylinder is reduced. It will be challenging to create a sufficient seal for effective combustion if the skirt is worn. Additionally, the piston will rob the cylinder violently, resulting in a piston slap. This will result in piston slap sounds, especially during cold starts. The moment the engine warms up, the noise will abruptly stop. This is so that the space between the piston and cylinder may be closed by the ensuing expansion. If the noise persists, the cylinder may need to be tightened in addition to likely requiring some additional action. If not, the problem can end up doing more harm to the engine.

Piston rings

Piston rings are the pieces of split rings that are mounted on a recess area of the piston. In an engine, there are typically three piston rings. Depending on the type of engine, the ring may occasionally only be one. A piston ring’s main purposes are to manage the amount of lubricating oil used and to seal off the combustion chamber. In addition, the rings aid in transferring heat away from the cylinder bore. The compression ring refers to the first ring that is closest to the combustion chamber. It is also known as a pressure or gas ring. Additionally, it transfers heat from the piston to the cylinder walls and stops combustion gas leaks. The ring situated between the compression and oil rings is known as the scraper or wiper ring. It fulfills the role of the first and last rings and has a tapering form. Its functions include closing the combustion chamber and removing oil from the cylinder walls of the piston. The bottom ring on the piston is the oil control ring, which is the last ring. It comprises two slender surfaces with holes around them. Its purpose is to drain extra oil from the cylinder walls and let the oil flow back into the sump.

Wrist pin / Piston pin

The wrist pin or gudgeon pin is another name for the piston pin, which is a piston component. The pin in the skirt part is the hollow or solid shaft. On this pin, a piston rod is secured in the piston ring bushing pivots. To provide a strong tensile strength, alloy steel is used to make piston pins. To accommodate the piston bearings, it is then machined. Through holes in the connecting rod, oil is delivered to this pin, assisting in the reduction of friction. The piston pin’s job is to provide bearing support so that the piston may operate as intended. This is so because the connecting rod and pistons are connected by the piston pins, which also serve as a pivot. This means that the pin helps the piston move back and forth. There are three different kinds of piston pins.

Connecting rod

One of the main components of a piston, the connecting rod is sometimes abbreviated as conrod or rod. It enables the piston’s movement inside the chamber and links it to the engine’s crankshaft. The component is strong enough since it is made to withstand mechanical stress. Forging and occasionally casting processes are used to create the piston pieces. Steel is the most common material used to make pistons since it is ideal for high-performance engines. When a lower-weight piston is required for gentler engines, aluminum is employed. The connecting rod’s job is to turn the crankshaft, which generates motion that moves the engine. This rod has a drilled hole that allows lubricating oil to be delivered to the wrist pin and cylinder walls. Connecting rods come in a variety of designs, including parallel and tapered rods, straight and angled separation rods, machined joints, crack joints, and separation rods with varying angles. A connecting rod has several parts, including

- Small end. The rod’s tiniest end, which includes the rod eye and piston bushing. Through a piston pin, this small end is connected to the piston.

- The big end of the rod is the portion that is opposite the little end. The crankshaft is attached to it. Finally,

- Beam that connects the tiny and large portions of the rods. The typical structure is a double T, and an oil tube to deliver oil to the cylinder may or may not be included.

Piston bearings

The bearings are excellent piston components that increase the movement’s efficiency. It is situated where pivotal rotation takes place. Typically, these points’ bores are filled with semicircular metal pieces that serve as bearings. The piston’s bearing is made up of shells in the large end where the rod attaches to the crankshaft. The component is frequently made from metals such as silicon aluminum, copper, etc. To increase hardness and provide them the capacity to endure the weight of the piston and the motions of the connecting parts, it is further coated.

The function of an Engine Piston

Movement of the engine piston

The piston in the cylinder goes up and down when the engine runs. The piston slows down as it approaches the turning point before abruptly resuming its acceleration. The piston is subjected to inertia forces as a result. This creates the piston force, which is transmitted to the connecting rod and crankshaft when combined with the forces produced by the gas pressure. Only at the upper and lower turning points are the connecting rods perfectly vertical. The piston is forced up against the side of the cylinder wall by the connecting rod’s tilt. The amount and direction of this force constantly change during the combustion cycle, as they depend on the piston force and the angle between the piston crown and connecting rod axis. Pistons are equipped with piston rings. They seal the combustion and working chamber about the crankcase. They reduce oil usage by removing oil from the cylinder walls as well. The cooled running surface of the cylinder liner receives the heat that the piston absorbs during combustion thanks to the piston rings.

Role in the combustion process

It is possible to describe combustion as the quick oxidation of a fuel that produces heat and light. In other words, combustion creates heat from the energy held inside the fuel’s molecular bonds. Combustion takes place in an engine as a flame that spreads throughout the cylinder. If three elements are present—fuel, an oxidizing agent (oxygen), and heat—a flame (fire) will result. Depending on the fuel type, the heat required for the flame to ignite comes from either a spark (for gasoline or diesel engines) or hot (compressed) air. We use internal combustion engines as propulsion systems because their primary output is mechanical power. Exhaust gases are produced as a by-product together with mechanical power. The only gases that remain once combustion is finished are carbon dioxide (CO2) and water vapor (H2O). In actuality, the exhaust gases also comprise pollution emissions such as oxides of nitrogen (NOx), unburned hydrocarbons (HC), carbon monoxide (CO), soot/particles (PM), polyaromatics, aldehydes ketones, and nitro-olefins, primarily as a result of incomplete combustion.

Transfer of energy

The conversion of thermal energy into mechanical work and vice versa is facilitated by a piston. Pistons function by transmitting the force output of an expanding gas in the cylinder to a crankshaft, which then gives rotational momentum to a flywheel. As a result, pistons are a crucial part of heat engines.

Four-Stroke Cycle for Engine Pistons

Intake stroke

The air-fuel combination is delivered to the combustion chamber during the intake event. The intake event happens when the intake valve is open and the piston transitions from TDC to BDC. There is a low pressure in the cylinder as a result of the piston moving toward BDC. The air-fuel combination is forced into the cylinder through the open intake valve by ambient atmospheric pressure to fill the low-pressure region produced by the piston action. The air-fuel mixture continues to flow by its inertia while the piston starts to shift direction, and the cylinder fills slightly past BDC. After BDC, the intake valve is still open by a small amount of crankshaft rotation. based on the engine’s design. The air-fuel combination is then trapped within the cylinder once the intake valve shuts.

Compression stroke

The trapped air-fuel combination is pressurized during the compression stroke inside the cylinder. To create the charge, the combustion chamber is shut. The charge is the quantity of compressed air-fuel combination that is waiting to ignite within the combustion chamber. More energy may be released when the charge is ignited thanks to the compression of the air-fuel combination. To guarantee that the cylinder is sealed and ready to deliver compression, the intake and exhaust valves must be closed. Compression is the process of shrinking or condensing a charge in the combustion chamber from a big volume to a smaller volume. The flywheel aids in preserving the force required to compress the charge. Heat is produced when an engine’s piston compresses the charge because the piston’s increased effort produces more compressive force. The charge temperature and the amount of fuel vaporized both rise as a result of the compression and heating of the air-fuel vapor. To facilitate quicker fuel oxidation after ignition, the charge temperature rises steadily throughout the combustion chamber. The increase in fuel vaporization happens as little fuel droplets evaporate more thoroughly due to the heat produced. More of the charge may be burned completely in the combustion chamber due to the greater droplet surface area exposed to the igniting flame. Only the gas vapor itself ignites. Gasoline can emit more vapor by having larger droplet surfaces as opposed to staying liquid. The amount of energy produced by burning increases with the compression of the charge vapor molecules. The energy required to compress the charge is far lower than the increase in force brought about by burning. For instance, the energy needed to compress the charge in a typical compact engine is just a quarter of the energy generated during combustion.

Power stroke

The piston head is forced away from the cylinder head during the engine’s power stroke by hot, expanding gases. To deliver torque to the crankshaft, piston force, and subsequent motion are transmitted through the connecting rod. The crankshaft starts to rotate when torque is applied. The pressure on the piston, the piston’s size, and the engine’s throw all affect how much torque is generated. Each valve closes during the power stroke.

Exhaust stroke

The exhaust stroke occurs when spent gases are expelled from the combustion chamber and released into the atmosphere. The exhaust stroke, which is the last one, happens when the intake and exhaust valves are both closed. Gases from the exhaust are released into the atmosphere by piston action. During the power stroke, combustion is finished, and the cylinder is filled with exhaust gases when the piston hits BDC. Exhaust gases are forced to exit via the open exhaust valve when the exhaust valve opens, and this happens because the flywheel and other moving elements’ inertia drive the piston back to the top dead center. The piston is at the top dead center (TDC) and one working cycle has ended after the exhaust stroke.

Conclusion

In conclusion, an internal combustion engine’s piston is an essential part that aids in the conversion of heat energy into mechanical work and vice versa. It is made up of several components, including the wrist pin, connecting rod, piston head, piston skirt, and piston rings. The piston skirt goes up and down the cylinder while the piston head controls knocking and creates a swirl for even combustion. The combustion chamber is sealed off by the piston rings, which also regulate the quantity of lubricating oil utilized. The connecting rod connects the piston to the engine’s crankshaft, while the wrist pin supports the piston’s bearing. The kind of engine and required performance have an impact on the piston’s design. To guarantee optimal engine operation and prevent damage, it is crucial to maintain the piston and its parts.