Cars are comprised of numerous parts and components, and in this article, we will discuss the clutch, one of the most vital elements that ensures a comfortable ride for the driver and passengers. Here are the most important details regarding clutches and their operation.

Components of a Clutch

A clutch is a mechanical device that transmits power from the driving shaft to the driven shaft. It does this by pulling the driving shaft toward the driven shaft. One shaft is connected to the engine or power unit (the driving member), while the other shaft provides the power output that performs the task.

Flywheel

This clutch component is attached to the crankshaft; it operates as long as the engine is operating. A friction disc is affixed on the flywheel’s outer side. The flywheel serves three primary purposes. Maintaining a rotating mass (inertia) is the primary goal, since this will make it easier for the engine to rotate and will result in more consistent torque delivery while it is in use. The second step is to equip the starter motor with a ring gear. The third step is to equip the friction disc with one of its driving friction surfaces.

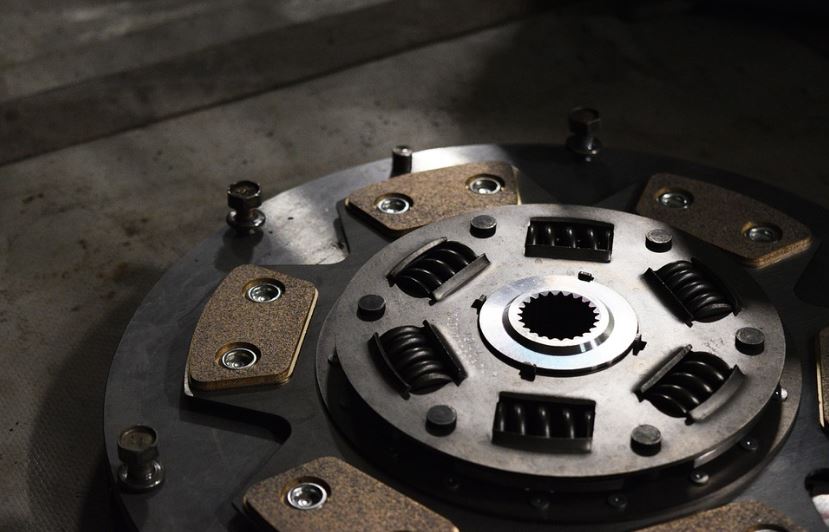

Friction Disc

Depending on the application, the friction disc may consist of a single disc or multiple discs. A material with a high coefficient of friction is used to construct it. On a drive shaft is affixed the friction disc. A spline connects the friction disc to the transmission input shaft. The disc powers the transmission’s input shaft, which transmits motion to the wheels. The disc contains a sacrificial friction material that enables the clutch to be modulated in order to regulate the drivetrain when accelerating from a stop. In addition, the disc has a spring-loaded hub that dampens engine vibration when the clutch is engaged. This hub also dampens torque when the drive is engaged and disengaged.

Pressure Plate

The pressure plate is the most important component of the clutch assembly as a whole. The pressure exerted by the pressure plate holds the powered friction disc between it and the flywheel. The pressure plate and flywheel are bolted together and rotate together. The driving surface or the main casting receives pressure from the pressure plate, which may be equipped with a diaphragm or springs to do so. It is necessary to press down on the diaphragm or clutch levers in order to release the drive or disengage it. This will allow the main casting to rise up and away from the driven disc. On the pressure plate is an additional friction disc. This pressure plate is attached to the hub’s splined shaft.

Spring and Release Levers

The function of the springs is to oscillate the friction disc. The spring used in clutches is a diaphragm spring, which is retracted by levers. The release mechanism establishes the connection between the rotating clutch assembly and the transmission via the static clutch fork. In addition to absorbing the force required to disengage the clutch, the bearing will reduce wear between rotating and non-rotating components.

How a Clutch Works

Automatic transmissions contain multiple clutches. They also contain other components that serve as “clutches.” They lack a single or dual clutch that connects the engine to the axles and sets the vehicle in motion, as a manual transmission/ clutch does. This task is performed by a torque converter or viscous drive.

In an automatic transmission, the clutches are normally engaged by hydraulic pressure working on an internal piston (or many pistons), and they are subsequently disengaged by springs. This process is repeated whenever the transmission is in manual mode.

A clutch pack controls the movement of planetary gear sets to allow an automatic transmission to engage the appropriate gear. Inside the transmission, a piston compresses several narrow discs to form clutch packs. These pair-functioning discs are either steel discs or friction discs.

There are numerous clutch designs available, depending on the application. The majority of automotive clutches are single-plate dry clutches with two friction surfaces. The purpose and operation of a clutch, regardless of the context in which it is used, is to transfer torque from a motor that is used for rotating movement to a gearbox.

A clutch consists of two rotating shafts, one of which is operated by a motor or pulley and the other by another device. The clutch is what makes it possible for the two shafts to be linked together and rotate at the same speed, or decoupled and rotate at speeds that are different from one another.

Clutches need some kind of actuation mechanism in order to prevent the transmission of torque. The clutch pedal is a lever used to disconnect propulsion from the engine to the transmission from within the vehicle. The pedal converts the clutch pedal’s parabolic oscillation into a linear movement. This linear movement is then converted into thrust bearing movement via displacement of mechanical links, cable, or hydraulic fluid.

It is helpful to have an understanding of friction in order to know the workings of a clutch. Friction is a measure of how difficult it is for one thing to glide over another. Friction is caused by the peaks and valleys on every surface; even the smoothest surfaces have infinitesimal peaks and valleys. The greater the size of these peaks and valleys, the more difficult it is to transport the object. The friction between a clutch plate and a flywheel makes a clutch function.

In an automobile, a clutch is required because the engine spins continuously while the wheels do not. To halt a vehicle without turning off the engine, the wheels must be disconnected from the engine. By regulating the slippage between the engine and transmission, the clutch enables a smooth connection between the two.

The clutch is designed to engage and disengage the connection between the flywheel of the engine and the input shaft of the transmission. When the clutch pedal is depressed within the vehicle, the clutch disengages; when the pedal is released, the clutch engages.

When the clutch lever is depressed, the release fork is pushed by a cable or hydraulic piston. In turn, this pressures the release bearing, which disengages the engine from the transmission during gear changes, against the center of the diaphragm spring. When the middle of the diaphragm spring is compressed, a series of pins located near the spring’s exterior cause the spring to pull the pressure plate away from the clutch disc. This disengages the clutch from the engine’s rotation.

Consider the clutch plate’s springs. These springs assist in isolating the transmission from the impact of the clutch engagement.

The Process of Shifting Gears

The first of three essential foundational skills you must master is gear shifting, followed by steering and clutch control. Up and down gear changes are possible. This has nothing to do with the direction in which the gear lever is moved; it simply indicates whether the driver is shifting to a higher gear (4 or 5) or a lower gear (1 or 2).

The general norm is to shift up through the gears as the vehicle’s speed increases and down when more engine power is required. For instance, you would shift into a lower gear when ascending a hill or accelerating slowly. The ratios determine the quantity of available engine power.

The ability to shift ratios in a vehicle with a manual transmission requires considerable practice. You must use your left foot to operate the clutch accelerator while using your right hand to manually select the desired gear.

When the clutch lever is depressed, the transmission’s connection to the wheels is disengaged. This prevents engine power from being transferred to the axles. While maintaining pressure on the clutch lever, the driver shifts gears.

First gear offers the most drawing power but the least speed potential, whereas fifth gear, which offers the least pulling power, offers the greatest speed range. The following table details the typical speed and engine revolutions when shifting up or down a gear.

When the engine is off and the clutch pedal is fully depressed, you can practice shifting the gear shift lever into the various ratios until you are confident in their locations. When driving, you must be able to locate each gear without looking at the gear shift.

Be sure to remove your foot from the clutch pedal each time you complete a gear change while traveling. Leaving your foot on the clutch lever unnecessarily is known as “riding the clutch” and can increase clutch wear. Not pressing the clutch pedal all the way down when shifting gears is a common error, particularly among novice motorists. It should be pressed as close as feasible to the floor of a car during this operation.

To conclude

The clutch is a bit of an unsung hero: while the engine and transmission hog the limelight, the one component that enables those two to function so seamlessly together is virtually invisible. Yet without the clutch, our manual-transmission vehicles would be little more than yard art. The humble contraption of friction disc, pressure plate, and diaphragm spring is the secret to perfect downshifts on your beloved winding back road.

Not all downshifts and backroads are ideal, however. Your clutch can withstand virtually unimaginable amounts of abuse, but it is not infallible. If you ride it a bit too aggressively or treat it a bit too roughly, you’ll end up bearing a painfully large repair bill. Before you reenact your beloved Fast and Furious scene, consider this a friendly reminder that clutch jobs aren’t inexpensive.

Fortunately, treating your clutch with a modicum of deference and refraining from abusing it outside of specific low-speed situations is a foolproof way to prolong its life and prevent it from developing a smoking habit. Smoking a clutch can result in health concerns for automobiles. If you refrain from doing so, your clutch should outlive you by a wide margin.