The clutch is often considered the hardest-working part of a vehicle. Responsible for facilitating stopping, starting, and shifting gears, it constantly has to disengage and reengage. This creates a lot of heat from all of the friction and pressure and can wear it out over time.

At the same time, it’s dangerous to drive with a failed clutch because it can break apart and stop the vehicle from running. What is more, when the clutch is not operating properly, other issues are sure to promptly ensue.

This article will explore how the clutch works, how to tell if something is wrong with it, and why.

View here to learn more about throttle control handle.

How Clutches Operate

A clutch is a widely used engineering device; not even just strictly a key element for motor vehicles, but for many items, like drills or chainsaws for example. It connects two devices to enable them to either rotate at the same speed, or separate and rotate at different speeds. For motor vehicles, this is so important because it allows the wheels to stop running, while the engine may remain running. In other words, it can stop the vehicle without stopping the engine.

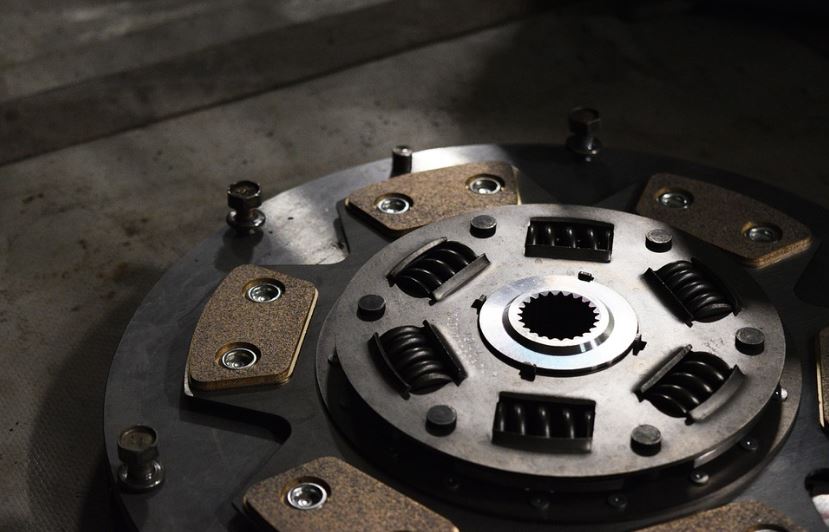

It’s composed of a flywheel, a clutch disk that bolts up to it, and a pressure plate that holds them all in place. When your foot is off the pedal, the engine and the transmission shaft will spin at the same speed as springs push the pressure plate into the disc. Because the flywheel is connected to the motor, when it’s pushed by the disc it will engage the motor. Alternatively, when the clutch pedal is pushed, the pressure plate moves away from the clutch disk to isolate the engine from the transmission, using friction. As the flywheel is connected to the motor, this friction stops the motion.

Reasons Why Clutches Fail

Even though truck clutches are built to withstand more pressure and wear, they experience enough wear and tear on their long journeys to still be vulnerable. Here are reasons they may give out:

Pressure plates are compromised

Eventually, pressure plates wear out and can’t put pressure on the clutch disk and flywheel.

Cables are worn-out

The cables won’t have the tension they need to properly engage and disengage the clutch.

Cylinders are leaking

Some clutches rely on fluid to build and release pressure.

Incompatible new clutch

You may have to change out surrounding parts so they can work together.

The Clutch May Be Failing If

- You see puddles under the truck

- You smell burning oil

- You hear a squeaking sound

- You feel a rattling when you let go of the clutch

- The clutch pedal feels soft

- The clutch feels like its sticking and may sound like it’s grinding

- The truck is harder to shift suddenly or feels like its slipping

Clutches are necessary and particularly important to a number of applications.