The engine is the heart of your vehicle. It’s a sophisticated machine that uses the heat from burning gas to turn the wheels. This is accomplished through a series of reactions that begin when a spark ignites a mixture of fuel and compressed air in a momentarily sealed cylinder that burns rapidly. When the mixture burns, it expands and provides energy to propel the vehicle.

There are two types of engines: those that burn gasoline outside the engine and those that burn fuel inside the engine. Let’s find out what an external combustion engine is and how it differs from an internal combustion engine.

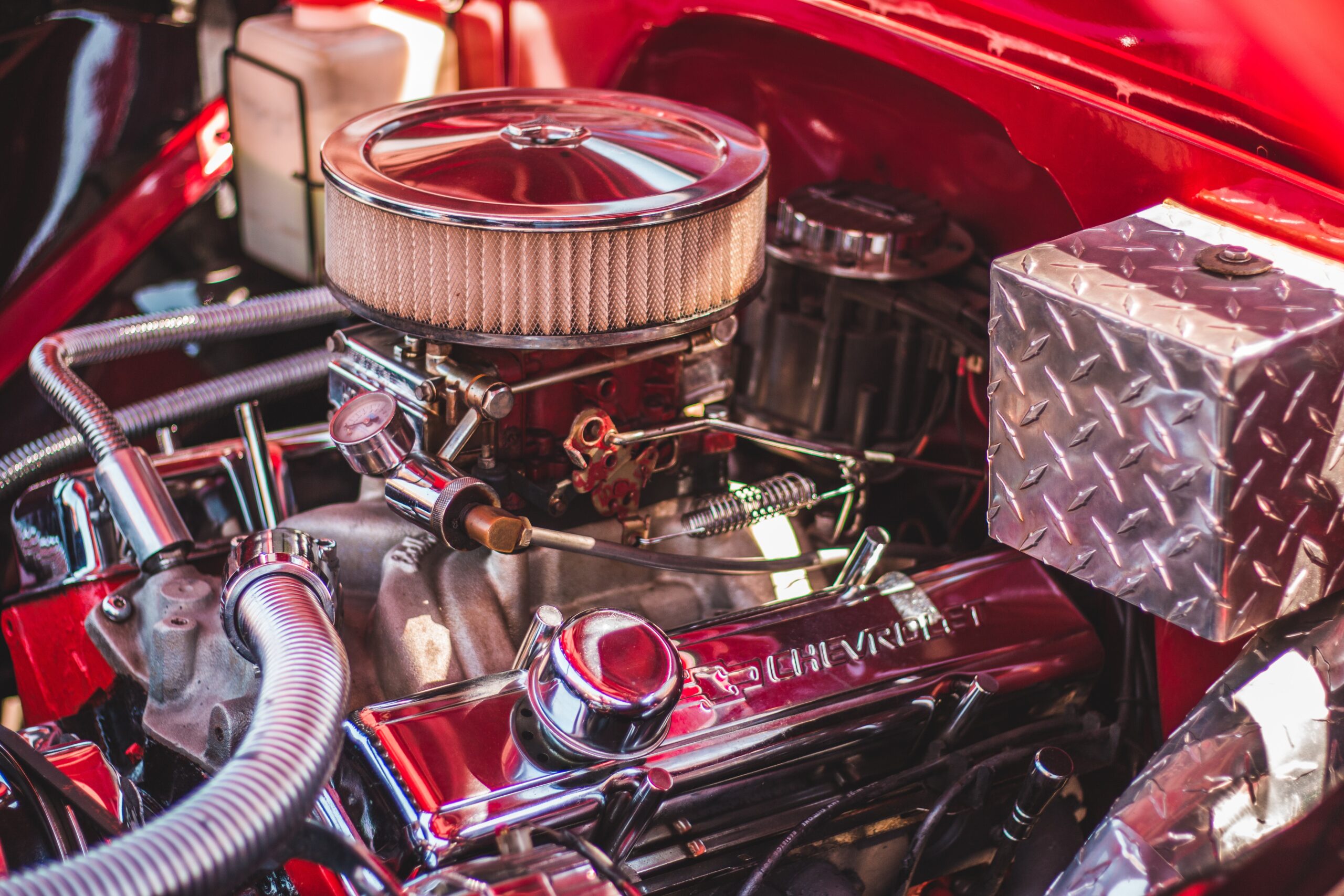

Internal Combustion Engines

A. Definition

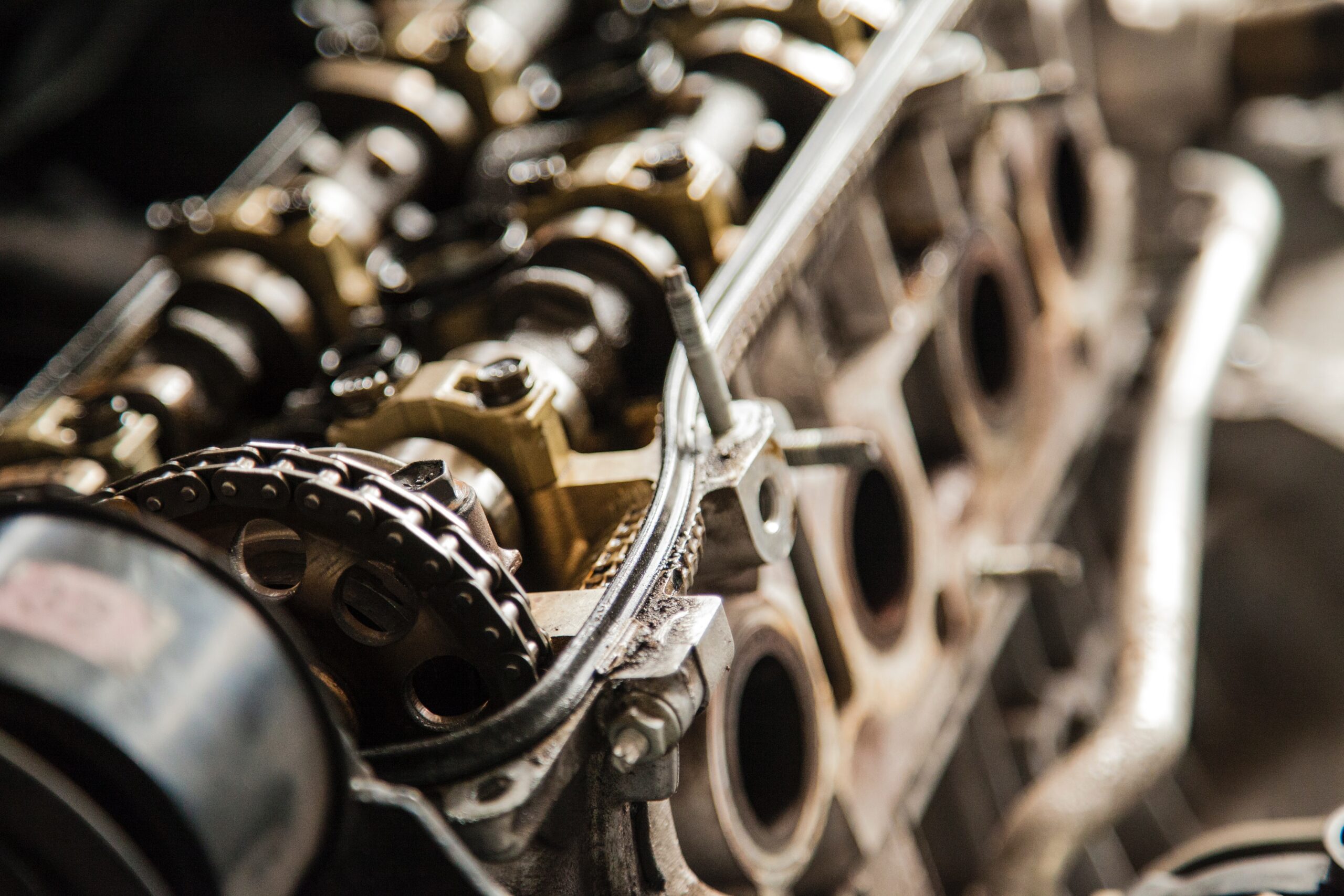

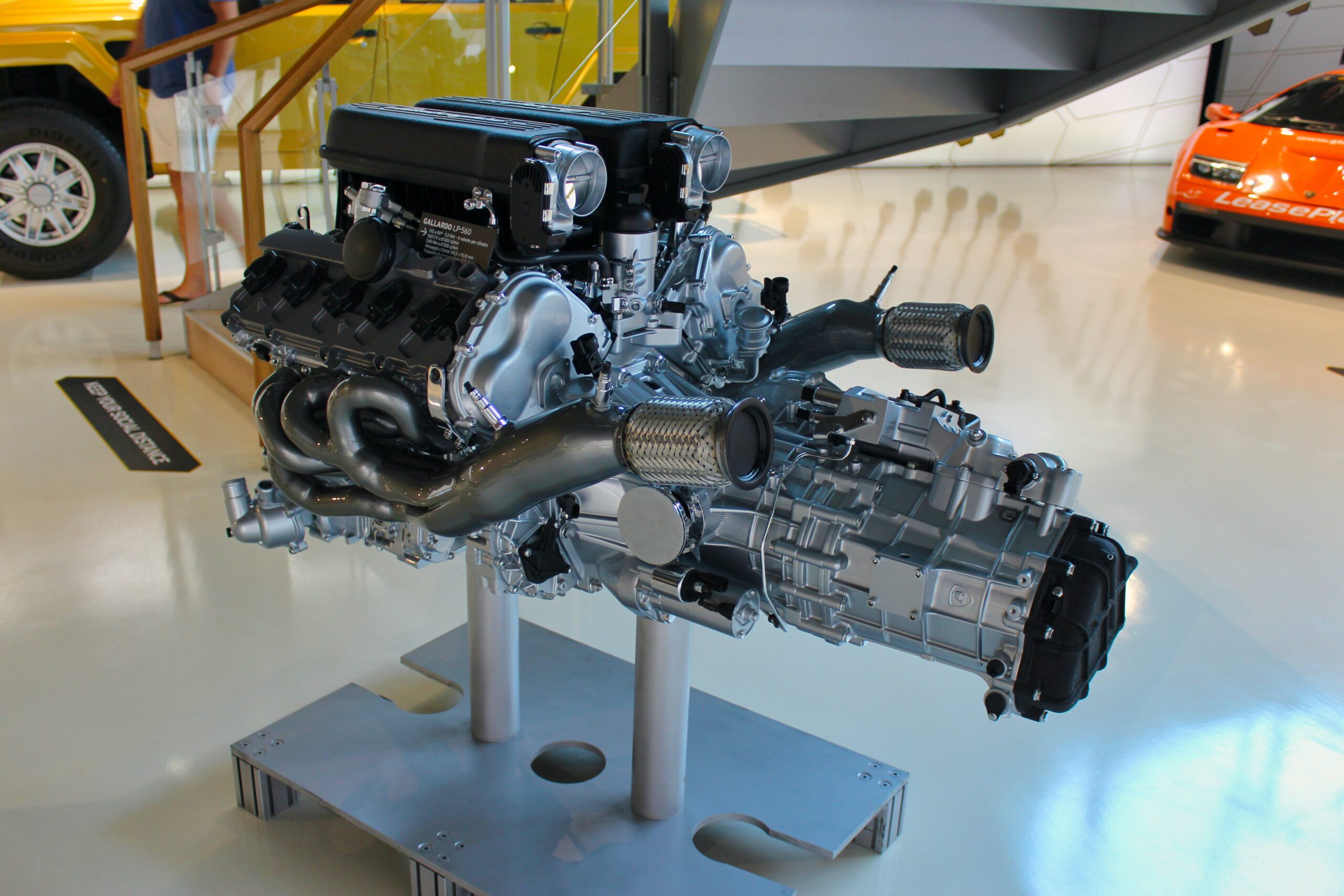

Internal combustion engine (ICE) is a form of heat engine that transfers the chemical energy held in fuel into mechanical energy by combustion within the engine. The fuel is ignited in a combustion chamber, causing a fast expansion of hot gases that drive a piston, providing mechanical work. This technique is done in a number of cycles to provide continuous power.

Heat engines convert thermal energy into mechanical energy by employing a heat source to produce high-pressure gas that drives a piston or turbine, which generates mechanical work. Internal combustion engines are a form of heat engine that employs combustion within the engine to generate heat.

B. Types of Internal Combustion Engine

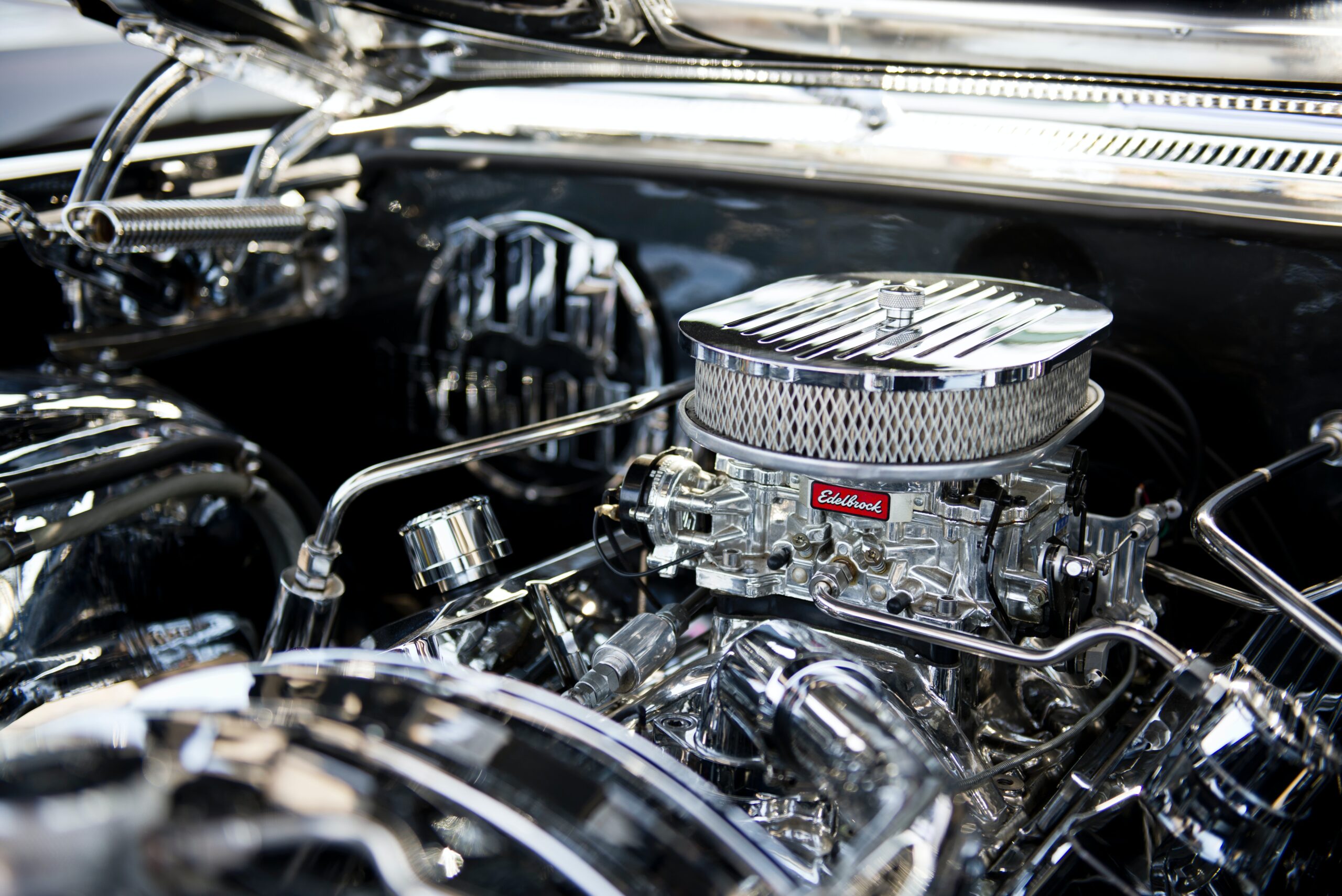

1. Spark Ignition Engine

Spark ignition is the process by which a spark lights the mixing of air and fuel in the combustion chamber of an internal combustion engine. During the entry stroke of a spark-ignition engine, air and fuel are mixed and then sucked into the cylinder. At the end of the compression stroke, a spark plug makes a spark that fires the mixture, causing it to burn and release energy. The engine is then powered by the energy that is turned into mechanical energy.

Cars, bikes, and small engines like lawnmowers and chainsaws often have engines that use spark ignition. Most of the time, they run on gasoline, which is a fuel that is easy to evaporate and mixes well with air. Spark ignition engines use more gas than diesel engines, but they make less pollution and are easier to start when it’s cold. The spark ignition system is an important part of the engine that needs to be built and kept in good shape for it to work well.

2. Diesel Engine

A diesel engine, also known as compression ignition engine, is a type of internal combustion engine that works by putting a lot of pressure on the air inside the engine cylinder. This raises the temperature inside the cylinder. The diesel fuel that is shot into the cylinder is then set on fire with this heated, compressed air. The energy that is released when something burns is turned into spinning mechanical energy that can be used to power machines or move a car.

Diesel engines are often used in heavy-duty applications like trucks, buses, and building equipment. They are also used in smaller vehicles and stationary applications like generators. People often choose them over gasoline engines because they use less fuel and last longer, but they tend to put out more pollution, which has led to efforts to improve their emissions performance. Modern diesel engines use advanced technologies like direct injection, turbocharging, and the recirculation of waste gas to use less fuel and make less pollution.

3. Wankel Engine

The Wankel engine, also known as rotary engine, is a special kind of internal combustion engine that uses a rotating design instead of the usual piston-and-cylinder setup. The engine has an oval-shaped body that holds a rotor that spins inside it. The rotor is in the shape of a triangle and has three convex faces that squeeze air and fuel as they spin around the housing. The housing has an inlet port, a combustion chamber, and an exhaust port. As the rotor turns, it moves over each of these ports, causing the engine cycle to happen. The rotary form of the Wankel engine makes it easier to build, has fewer moving parts, and is smaller than other types of engines. It is also known for having a high power-to-weight ratio and running more smoothly because it rotates.

However, the Wankel engine has some drawbacks as well. It uses more fuel than regular engines, has higher pollution, and can have problems with sealing and lasting. Because of these problems, the Wankel engine hasn’t been widely used in the auto business, but it is still used in some niche applications like sports cars, motorcycles, and airplanes.

4. Homogeneous Charge Compression Ignition (HCCI)

Homogeneous Charge Compression Ignition (HCCI) engines are a type of internal combustion engine that uses both spark ignition and compression ignition. HCCI engines use a lean mixture of air and fuel that is squeezed until it ignites on its own because the combustion chamber is so hot and pressurized. HCCI engines are different from traditional engines because they don’t use a spark plug to start the combustion process. They also don’t need a separate fuel pump like compression ignition engines do.

The lean mixture of air and fuel burns more fully and makes less pollution, like nitrogen oxides and particulate matter, which are bad for the environment. This is one of the benefits of HCCI engines. But HCCI engines can be hard to run because it’s hard to control the time of the ignition and the engine may be hard to start when it’s cold outside. Also, for HCCI engines to work well and consistently, the fuel system and engine design might need to be changed.

5. Stratified-Charged Engine (SCE)

The stratified-charge engine (SCE) is a type of spark-ignition engine that has features of both spark ignition (SI) and diesel engines. Like a diesel engine, the SCE runs on a combination of air and fuel that is too little and not mixed evenly in the combustion chamber. Instead, the fuel is injected straight into a small, highly concentrated area of the combustion chamber, while the rest of the air stays relatively lean. This makes a stratified mixture that can be lit more easily and burns more efficiently than a smooth mixture. This saves fuel and reduces pollution.

The SCE is often used in smaller engines, like those in motorcycles and small cars, because it can save fuel and reduce pollution without hurting speed. But compared to regular SI engines, the SCE has some drawbacks, such as a limited range of operation and the need for more modern fuel injection and ignition systems.

6. Gas Turbines

Gas turbines, also known as combustion turbines, are a form of internal combustion engine that uses a continuous combustion process to transfer the energy from a fuel, often natural gas, into mechanical energy. They are made up of three parts: a compressor, a combustion chamber, and a turbine. The compressor takes in and compresses the air, which is then mixed with fuel and ignited in the combustion chamber, resulting in a high-temperature, high-pressure gas that expands through the turbine and generates power. Gas turbines are commonly used to generate power in a variety of applications, including power plants, aviation propulsion, and as mechanical drivers for compressors and pumps in the oil and gas industry.

7. Atkinson Cycle Engine

The Atkinson cycle engine is a type of internal combustion engine named after its inventor, James Atkinson. It is a variant of the Otto cycle engine, which is the most prevalent form of internal combustion engine seen in automobiles. The Atkinson cycle engine has a longer power stroke than the intake and compression strokes, which results in better fuel efficiency. This is accomplished by closing the intake valve after the piston has passed the bottom dead center (BDC) position but before the end of the intake stroke. This minimizes the amount of air that enters the cylinder, which in turn reduces the amount of fuel required to reach the correct air-fuel mixture. The Atkinson cycle engine is typically used in hybrid automobiles, where it works in tandem with an electric motor to increase fuel economy.

C. Advantages and Disadvantages

Advantages of internal combustion engines:

1. Internal combustion engines are relatively small and light, but they can make a lot of power. Because of this, they can be used in a wide range of places, such as cars, boats, planes, and power sources.

2. Can store a large amount of energy in a compact space, making it an ideal option to power cars and other equipment.

3. Can be quickly and easily refueled, and gasoline or diesel fuel is readily available at gas stations and other locations.

4. Generally affordable to manufacture and maintain, making them an economical choice for a wide range of applications.

Disadvantages of internal combustion engines:

1. Put out gases and particles into the air, such as carbon dioxide, nitrogen oxides, and particulate matter, which add to air pollution and climate change.

2. They can be loud and shaky, which can be annoying for both riders and drivers.

3. Need regular maintenance such as changing the oil, replacing the air filter, and getting a tune-up, which can take time and cost money.

4. Less efficient than electric motors, consuming more fuel and emitting more pollution for the same amount of work.

External Combustion Engine

A. Definition

An external combustion engine is a form of heat engine that generates mechanical energy by transferring heat from an external source to a working fluid rather than directly burning fuel inside the engine. In contrast, an internal combustion engine burns fuel directly inside the engine to generate mechanical energy.

External combustion engines typically employ a heat exchanger or engine walls to transmit heat from an external source, such as burning coal or wood, to a working fluid, such as water or air. The working fluid is then sent to a cylinder, where it drives a piston, which is coupled to a crankshaft to generate rotational energy.

B. Types of External Combustion Engine

1. Steam Engine

The steam engine is a type of heat engine that uses steam to generate mechanical work. It was invented in the early 18th century and played an important part in the Industrial Revolution, powering a variety of machinery including textile mills, power plants, and locomotives.

A steam engine works by transferring heat energy from a fuel source such as coal or wood to water, which is subsequently turned into steam. The steam is routed to a piston or turbine, which generates mechanical energy that can be used to do work. The steam engine was a significant improvement over older engines that relied on the force of falling water or wind to generate power, as it allowed for more efficient and diverse energy use. Despite being completely superseded in the 20th century by internal combustion engines and electric motors, the steam engine remains an important element of engineering and technology history.

2. Stirling Engine

The Stirling engine is a closed, regenerative thermodynamic cycle heat engine. It was invented in 1816 by Robert Stirling and has since been utilized for a variety of purposes ranging from energy generation to submarine propulsion. The engine generates mechanical work by heating and cooling a set amount of gas, commonly air. What distinguishes the Stirling engine is its remarkable efficiency, especially when compared to other heat engines such as the steam engine. This is because the Stirling engine uses a thermodynamic cycle rather than combustion to generate power, and it has a closed-loop system that can be engineered to recover most of the heat that would otherwise be lost in other types of engines. Furthermore, the Stirling engine can be built to run on a variety of heat sources, including combustion and solar energy.

3. Brayton Cycle Engine

The Brayton Cycle is a thermodynamic cycle used to simulate the operation of gas turbines such as jet engines, aircraft engines, and power production turbines. Compression, heating, expansion, and cooling are the four steps of the cycle. Air is sucked into the turbine and compressed to a high pressure during the compression stage. During the heating step, fuel is injected into the compressed air and ignited, resulting in a high-temperature, high-pressure gas that powers the turbine. During the expansion stage, the heated gas expands through the turbine blades, providing mechanical energy that can be used to drive a generator or power a vehicle. Finally, during the cooling step, the gas is cooled and discharged from the turbine, completing the cycle.

4. Ericsson Cycle Engine

The Ericsson engine is a closed-cycle regenerative heat engine that uses the Ericsson cycle. It was designed in the 19th century by the Swedish inventor John Ericsson and was utilized in early submarines and trains.

The Ericsson engine employs an external heat source to heat a working fluid, typically air, which then expands and propels a piston or turbine. The expanded gas is then cooled and compressed before being heated again in a continuous cycle. One of the Ericsson engine’s distinguishing features is the employment of regenerators, which are heat exchangers that capture and store heat from the working fluid as it exits the engine and send it back to the fluid as it re-enters the engine. This improves engine efficiency by lowering heat loss and allowing for more thorough fuel combustion.

5. Hot Air Engine

A hot air engine, also called an air engine or caloric engine, is a type of heat engine that uses the expansion and contraction of air to make mechanical work. In a hot air engine, the air is heated from the outside, which makes it expand and drive a piston or fan, which in turn does work. The air is then cooled, which makes it shrink back to its original size and shape so it can be heated again.

Hot air engines were invented at the beginning of the 19th century and were used for many things, like pumping water, moving machines, and making power. They were finally replaced by more efficient internal combustion engines, but they are getting more attention again because they could be used in solar thermal power plants and other renewable energy applications.

C. Advantage and Disadvantages

Advantages of external combustion engines:

1. External combustion engines can use a wide range of fuels, including wood, coal, biomass, and even waste heat from industrial processes.

2. External combustion engines can achieve high thermal efficiencies, which means that they can convert a larger percentage of the fuel’s energy into useful work.

3. Lower speeds and generate less noise than internal combustion engines.

4. Produce lower emissions than internal combustion engines because they operate at lower temperatures.

Disadvantages of external combustion engines:

1. Typically have a lower power density than internal combustion engines of similar size and weight.

2. Take longer to start and reach operating temperature than internal combustion engines.

3. More complex and require more maintenance than internal combustion engines.

4. Typically larger and heavier than internal combustion engines of similar power output.

Applications of Internal and External Combustion Engines

A. Common uses of internal combustion engines

1. Transportation

Transportation is one of the most frequent applications for internal combustion engines because of their capacity to convert the chemical energy stored in fuels into mechanical energy, which may power a variety of vehicles such as cars, trucks, motorbikes, boats, and airplanes. Internal combustion engines are dependable, efficient, and powerful, making them an attractive option for transportation. They are also lightweight and compact, making them suitable for use in cars with limited space. Furthermore, the broad availability of fuels such as gasoline and diesel has made it simple to power cars with internal combustion engines, making them a popular mode of transportation worldwide.

2. Agriculture

Internal combustion engines are also widely used in agriculture. The capacity of these engines to provide a steady and consistent supply of power has been critical in supporting the efficient operation of various farming equipment, such as tractors, harvesters, and irrigation pumps. Internal combustion engines have increased farmer production by allowing them to accomplish operations such as plowing, planting, and harvesting considerably faster and more efficiently than conventional techniques. Furthermore, the portability of these engines has allowed farmers to simply relocate their equipment between fields, enhancing operating efficiency.

3. Power Generation

There are also many ways that internal combustion engines are used to make power. They can run electric generators in far-flung places or add to the grid when demand is high. Internal combustion engines are sometimes used in combined heat and power (CHP) systems. In these systems, the wasted heat from the engine is caught and used for heating or cooling, making the system more efficient overall. Diesel engines are often used in emergency power backup units in hospitals, data centers, and other important places. Gas turbines, which are a type of internal combustion engine, are also used in large-scale power plants, like those that run on natural gas.

4. Construction

Internal combustion engines have long been employed in the construction sector for a variety of purposes. These engines power heavy machinery like excavators, bulldozers, cranes, loaders, and generators. The engines give the essential power for difficult jobs like digging, lifting, and moving large things. Because of their high power-to-weight ratio, compact size, and fuel efficiency, internal combustion engines are popular in the construction industry. Furthermore, they are simple to maintain and repair, making them perfect for usage in severe construction sites.

5. Mining

Internal combustion engines power a variety of mining equipment, including excavators, bulldozers, loaders, drilling rigs, and vehicles. Equipment in the mining industry is frequently operated in hostile settings and subjected to enormous weights, making reliability a critical issue. Internal combustion engines are well-suited to these challenging conditions since they are sturdy, durable, and capable of generating high levels of power. Furthermore, diesel engines are particularly popular in the mining industry due to their excellent fuel efficiency and ability to work for extended durations without needing to be refueled.

6. Emergency Backup

Internal combustion engines are frequently utilized to generate emergency backup power, particularly in vital institutions such as hospitals, data centers, and military locations. These engines can instantly produce electricity to keep critical systems and equipment working in the case of a power loss or natural disaster. They can be powered by diesel, natural gas, or propane and come in a variety of sizes and capacities to satisfy a variety of requirements. Furthermore, many backup generators are engineered to start up and turn on automatically when power is lost, ensuring a smooth transition to backup power. It is crucial to highlight, however, that internal combustion engines used for backup power should be maintained and tested on a regular basis to guarantee they are ready to work when needed.

7. Lawn and Garden Equipment

Small internal combustion engines are usually what power lawn and garden equipment like lawnmowers, leaf blowers, and chainsaws. These engines are usually small four-stroke or two-stroke engines that run on gasoline or other fuels. They are used to power lawn and garden tools, like mowers that cut grass, leaf blowers that clear leaves and other waste, and chainsaws that cut trees and other plants. Lawn and garden tools with internal combustion engines are chosen because they are portable, powerful, and easy to refuel. But they also make noise and pollute the air, and they may use more fuel than other types of engines.

B. Common uses of external combustion engines

1. Marine propulsion

One of the most important applications of external combustion engines is marine propulsion. Steam engines were frequently employed in ships until the early 20th century, when diesel engines replaced them. Because they are reliable and can deliver significant power output, steam turbines are still utilized in some large ships, notably navy vessels. Stirling engines have also been employed in several small boats and submarines. The Stirling engine’s closed system allows it to operate on any heat source, including a small external fire, giving it a versatile and trustworthy option for naval propulsion.

2. Heating and Cooling

Stirling engines and other external combustion engines can be utilized for heating and cooling. Stirling engines are extremely adaptable, as they can be utilized as heat pumps, refrigerators, and air conditioning units. By simply reversing the direction of the power input or output, these engines may produce both heating and cooling effects. They are frequently employed in applications requiring dependable and efficient temperature management, including as spacecraft, submarines, and remote areas with limited access to electricity. Stirling engines are also noted for producing low levels of noise and vibration, making them an appealing alternative for applications where noise pollution is an issue, such as in residential and commercial areas.

3. Educational and research

External combustion engines, particularly Stirling engines, are extensively used to study thermodynamics and heat transport in educational and research contexts. These engines offer students and researchers an easy and practical way to examine thermodynamic principles and watch heat transfer in operation. The engines can be used to show thermal energy conversion into mechanical work, as well as heat transfer and thermodynamic cycle principles. External combustion engines can also be customized and refined for special research reasons, such as researching heat exchanger efficiency or testing the performance of new materials. External combustion engines have been used in research and education to improve understanding of thermodynamics and the creation of more efficient and sustainable energy solutions.

4. Solar Power

Solar energy is a renewable energy source that is gaining popularity due to its environmental benefits. Solar panels, on the other hand, can only convert sunlight into electricity during the day, and the amount of energy produced varies depending on the weather. External combustion engines, particularly Stirling engines, can be utilized to convert solar energy into mechanical or electrical energy, giving a more consistent and reliable power source. Stirling engines may run on heat created by concentrated solar power systems, which focus sunlight onto a tiny area and generate high temperatures. The heat is then utilized to fuel the Stirling engine, which drives a generator to generate electricity. This process can be repeated indefinitely, providing a consistent source of electricity even during cloudy or low-light conditions. Stirling engines also have a low environmental effect and can be built with low-cost materials, making them a viable and affordable option for solar power generation.

5. Waste Heat Recovery

Waste heat recovery is a critical application of external combustion engines, particularly Stirling engines, because they can transform low-grade waste heat into valuable work. This is especially useful in industrial settings where waste heat is created during production operations and can be captured and turned into electricity or other forms of energy. Industries may cut energy costs, enhance efficiency, and reduce their carbon footprint by adopting Stirling engines for waste heat recovery. Stirling engines are also highly reliable and require little maintenance, making them a practical and cost-effective waste heat recovery alternative.

6. Aerospace

Some aerospace applications have made use of external combustion engines, particularly Stirling engines. They have been investigated as prospective power sources for spacecraft due to their capacity to operate in severe temperature conditions, particularly for missions to planets with dramatic temperature swings. Stirling engines have also been employed in unmanned aerial vehicles (UAVs) for long-duration flights since they can operate for lengthy periods of time without refueling. However, the usage of external combustion engines in aircraft is still limited, and further research and development are required to fully realize their potential in this industry.

7. Military Applications

External combustion engines, notably Stirling engines, have been employed in military applications due to their dependability and ability to run on a range of fuels. They have been used to power unmanned aerial vehicles (UAVs) as well as auxiliary power units (APUs) for military vehicles and aircraft. The usage of Stirling engines in these applications offers various advantages, including quiet operation, low vibration, and decreased emissions. Stirling engines can also run on a number of fuels, including diesel, gasoline, and JP-8, making them handy in distant military sites where fuel supplies may be restricted. Their capacity to generate both heat and power makes them ideal for use in military tents and field hospitals.

8. Power Generation

External combustion engines, such as the Stirling engine and Brayton cycle engine, can be utilized for power generation due to their high thermal efficiency and ability to employ a range of heat sources, including solar energy and waste heat. These engines can be used in conjunction with other technologies such as turbines to generate electricity for homes, businesses, and industries. They can also be employed in isolated regions where standard power sources are unavailable or too expensive. Furthermore, external combustion engines have the ability to cut greenhouse gas emissions and improve sustainable energy generation.

Conclusion

Internal combustion engines and external combustion engines have substantial operational, efficiency, and application differences. Internal combustion engines generate power by burning fuel within the engine, whereas external combustion engines use an external heat source to generate steam or other working fluids. External combustion engines are normally more efficient and emit less pollutants, but they are also larger, more complex, and slower to respond to variations in power demand. Internal combustion engines, on the other hand, are more compact, adaptable, and widely employed in transportation, power generation, and other industries. Finally, the choice between these two types of engines is determined by the individual needs and requirements of each application.