In today’s technologically advanced world, electronic devices have become an integral part of our daily lives. From smartphones to medical equipment, everything relies on complex electronic systems that allow them to function efficiently. At the heart of these systems lies the Printed Circuit Board Assembly (PCBA), a fundamental component that plays a critical role in ensuring the proper functioning of electronic devices. This article delves into the various roles of PCBA and its significance in modern technology.

Introduction to PCBA

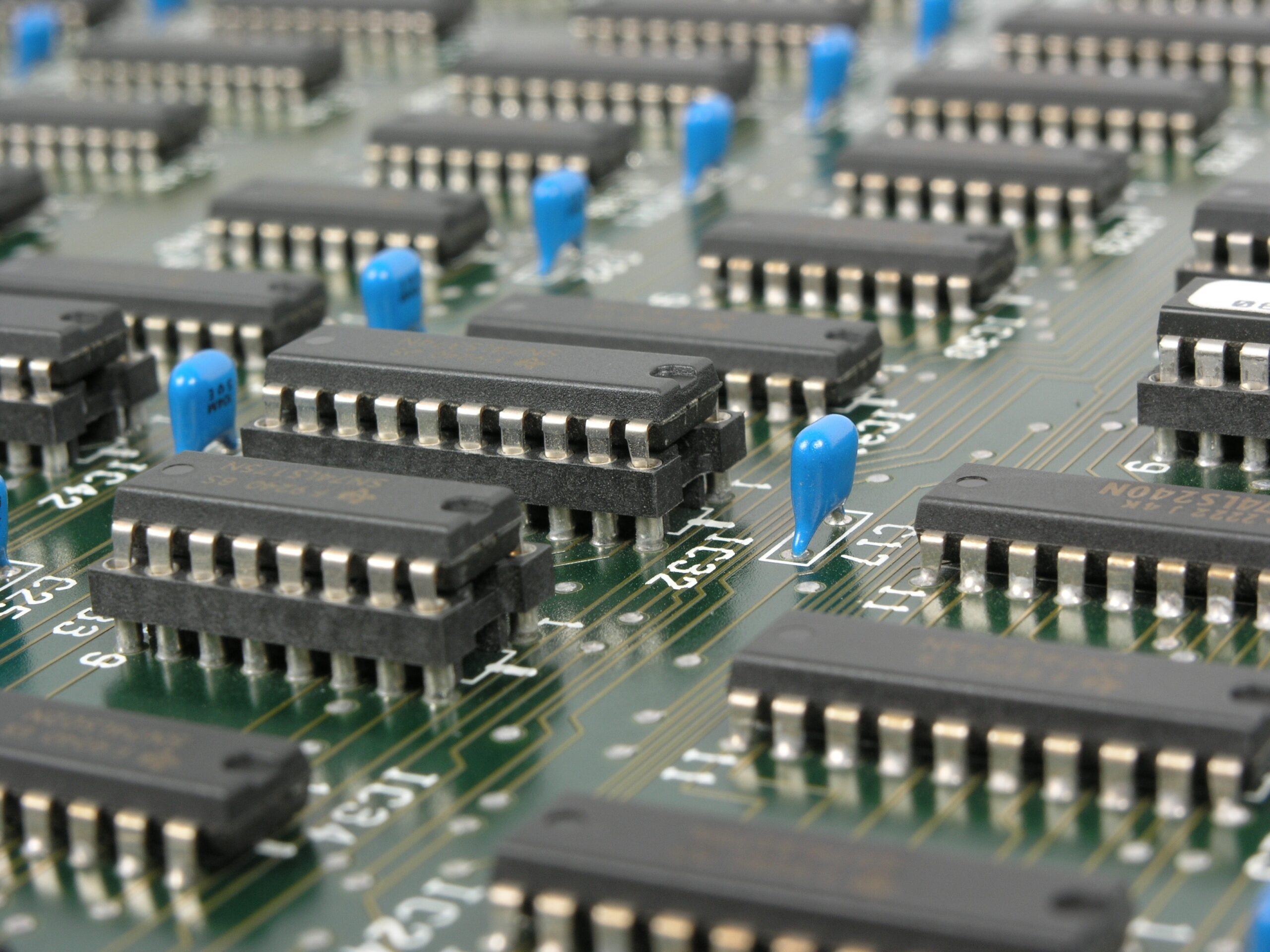

A Printed Circuit Board (PCB) is a flat, rigid board made from non-conductive material like fiberglass or composite epoxy, onto which electronic components are mounted. The process of attaching these components to the PCB is known as Printed Circuit Board Assembly (PCBA). This assembly process transforms a bare PCB into a functional device by populating it with active and passive electronic components such as resistors, capacitors, integrated circuits, connectors, and more.

Roles of PCBA

Component Mounting and Soldering:

One of the primary roles of PCBA is to provide a platform for mounting and interconnecting various electronic components. Components are placed on the PCB following a specific layout and then soldered into place. This soldering process ensures electrical connectivity between the components and the PCB traces, which are thin copper pathways that allow the flow of electrical signals.

Signal Transmission and Routing:

The arrangement of copper traces on the PCB is crucial for proper signal transmission between components. Different components need to communicate with each other, and the PCB’s layout determines the paths that electrical signals take. Careful consideration of signal integrity, minimizing interference, and optimizing the routing of high-speed signals are essential for preventing signal degradation and maintaining overall system performance.

Electrical Connectivity:

PCBA ensures electrical connectivity between various components on the PCB. This interconnectedness forms the foundation for the entire electronic system. Proper connectivity guarantees that components can communicate, share data, and work together seamlessly to achieve the desired functionality.

Mechanical Support:

Beyond electrical connections, PCBA also provides mechanical support for the components. The components are securely attached to the board, preventing them from moving or detaching due to vibrations, impacts, or thermal expansion. This mechanical stability is crucial in maintaining the device’s reliability and longevity.

Miniaturization and Space Optimization:

With the continuous trend towards smaller and more compact electronic devices, the role of PCBA in miniaturization cannot be overstated. By densely populating components on the PCB and optimizing the layout, PCBA contributes to the reduction of the overall size of electronic devices without compromising their functionality.

Thermal Management:

Many electronic components generate heat during operation. PCBA design incorporates thermal management techniques to dissipate this heat efficiently. Heat sinks, thermal pads, and careful component placement help prevent overheating, ensuring the longevity and reliability of the device.

Quality Control and Testing:

PCBA involves rigorous quality control processes to identify defects, such as soldering issues, incorrect component placement, or electrical connectivity problems. Advanced testing methods, including automated optical inspection (AOI) and X-ray inspections, are used to catch these issues and ensure that only fully functional PCBAs move forward in the production process.

Conclusion

Printed Circuit Board Assembly (PCBA) is a cornerstone of modern electronics, serving as the backbone upon which complex electronic systems are built. Its multifaceted roles, including component mounting, signal transmission, electrical connectivity, mechanical support, miniaturization, thermal management, and quality control, collectively contribute to the reliable and efficient operation of electronic devices. As technology continues to evolve, PCBA will remain a critical component in the advancement of various industries, shaping the way we interact with and benefit from electronic devices in our daily lives. If you are looking for a turnkey pcb assembly supplier that can maintain product quality, you can consult pcbasic.