As a car owner, you know the importance of a well-functioning brake system. Brake rotors are crucial to this system and need regular care to work effectively. This easy-to-follow guide will help you understand brake rotors, spot signs of wear, and offer tips to maintain them properly.

What are Brake Rotors?

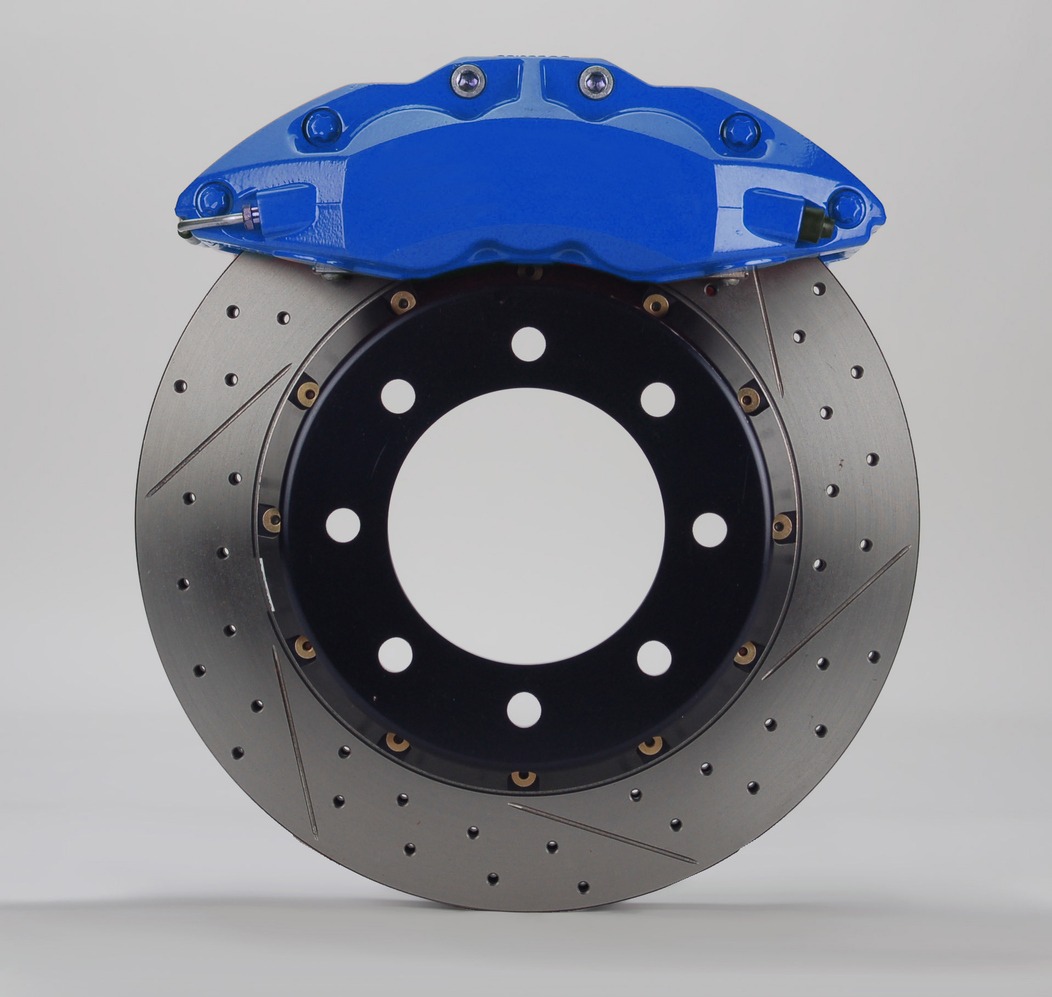

Brake rotors are circular discs connected to your car’s wheels. When you hit the brake pedal, the brake pads squeeze these rotors, creating friction that slows and stops your car. However, over time, this continuous heat and pressure can wear down the rotors, affecting their performance.

You’ll find brake rotors in a wide range of vehicles, from cars and trucks to buses, motorcycles, and even bicycles. They’re typically located at the wheel’s center, sandwiched between the tire and the hub, and are secured to the wheel with bolts or studs.

In a standard brake system, brake pads sit on the caliper, which wraps around the rotor. Pressing the brake pedal activates the caliper, squeezing the brake pads onto the rotor. This action creates the necessary friction to reduce speed or bring the vehicle to a halt.

Brake rotors are integral to the braking system, helping avoid accidents and ensuring a safe driving experience. A well-maintained brake system, including rotors that are in good condition, is essential for short stopping distances and consistent braking performance, especially in emergency situations. The condition of your brake rotors impacts the effectiveness of your brakes and, by extension, the overall safety of your vehicle.

Proper maintenance of your brake rotors is crucial for a safe and efficient braking system, as any issues can lead to road accidents. This guide will cover all you need to know about brake rotor maintenance, helping you keep your car’s brakes in excellent condition.

Types of Brake Rotors

Understanding the different types of brake rotors is crucial for selecting the right option for your vehicle. Each type offers unique characteristics and advantages, making them suitable for specific driving conditions and vehicle types.

Blank and Smooth Rotors

Solid brake rotors are a staple in the automotive world, predominantly found in standard vehicles. These rotors, crafted from cast iron, are known for their durability and cost-effectiveness. However, they have their downsides, such as being more susceptible to warping and potentially generating more brake dust than other rotor types.

When you buy a new passenger vehicle, you’ll usually find it equipped with blank and smooth rotors. These rotors are designed to meet the original equipment (OE) specifications. It’s important to note that OE-specific rotors come in two varieties: basic and premium. The kind you choose largely depends on your driving style and the type of vehicle you have.

For the everyday driver or those who don’t push their cars to the limits, blank rotors are an excellent option. These rotors provide sufficient braking power for normal driving conditions and are often preferred for their simplicity and reliability.

However, it’s crucial to understand the difference between the basic and premium types. Basic OE-specific rotors are typically made from recycled steel and may not perform as well as your original manufacturer’s rotors. This is mainly due to thicker internal fins affecting the rotor’s cooling efficiency.

If you’re planning to upgrade to premium ceramic brake pads, it’s advisable not to pair them with basic rotors. Why? Because basic rotors can diminish the lifespan of your new pads by wearing them down faster due to increased heat.

Drilled Rotors

Drilled brake rotors are distinguished by the holes drilled through their surface, a design feature with specific benefits and considerations. These holes are strategically placed to facilitate the dissipation of heat and gases, as well as to help clear debris away from the brake pads. This design makes them particularly effective in certain driving conditions.

One of the primary advantages of drilled rotors is their performance in wet environments. The holes in these rotors allow water, dust, and heat to escape more readily from the rotor’s surface. This quality makes them an excellent option for drivers in rainier climates, as they can significantly enhance stopping power in wet and slippery conditions.

However, it’s crucial to be aware of the limitations of drilled rotors, especially for those considering them for performance vehicles. Under high heat conditions, such as those experienced in racing or aggressive driving scenarios, drilled rotors may not be the best choice. They are more susceptible to cracking compared to their slotted counterparts due to the stress and heat concentration around the drilled holes.

Slotted Rotors

Slotted brake rotors are specialized to boost braking efficiency, particularly in demanding driving conditions. Featuring distinctive slots or channels on their surface, these rotors are tailored to manage effectively the heat and gas build-up that occurs during intense braking. The unique design also plays a crucial role in removing debris from the brake pads, which, in turn, enhances the overall braking performance.

Primarily, slotted rotors are an ideal choice for heavy-duty trucks and SUVs, especially for those vehicles frequently involved in towing or hauling heavy loads. The slots carved around the rotor’s exterior draw more air into the space between the brake pad and the rotor, significantly improving cooling and heat dispersion. This aspect is vital for maintaining optimal braking performance under strenuous conditions.

Additionally, these rotors are engineered to assist in clearing away excess brake debris and pad glaze, which is a common issue at higher temperatures. However, it’s worth noting that slotted rotors offer several efficiency advantages but have drawbacks. These rotors tend to have a shorter lifespan compared to other types, and this reduced durability can also affect the life of your brake pads.

Drilled and Slotted Rotors

Drilled and slotted brake rotors combine the best of both worlds, featuring both slots and holes on their surface. This design makes them exceptionally suitable for high-performance vehicles like sports cars, where efficient heat dissipation and debris removal are crucial. These rotors are especially beneficial for vehicles driven at high speeds, like during racing or on track days, where the braking system is subjected to intense heat and friction.

The unique combination of tiny holes and small trenches in these rotors serves a critical function. They act like gutters, channeling away water and heat, thereby minimizing the adverse effects of high-speed, high-performance driving. This feature is essential for maintaining the integrity of the rotors under the rigorous conditions of off-road or track driving.

However, it’s important to consider the downsides of drilled and slotted rotors. While they excel in heat dissipation, their durability can be a concern. The process of drilling and slotting removes material from the rotor’s surface, leading to faster wear on brake pads due to the edges wearing them down more quickly than traditional smooth surfaces. Additionally, this removal of material can compromise the rotor’s overall robustness, making it more susceptible to cracking under extreme conditions.

Carbon Ceramic Rotors

A mention should be made of less common but highly advanced types like carbon ceramic rotors. These are typically found in high-end sports cars and luxury vehicles. Carbon ceramic rotors are known for their exceptional performance, lightweight, and durability, but they cost significantly more than traditional steel rotors.

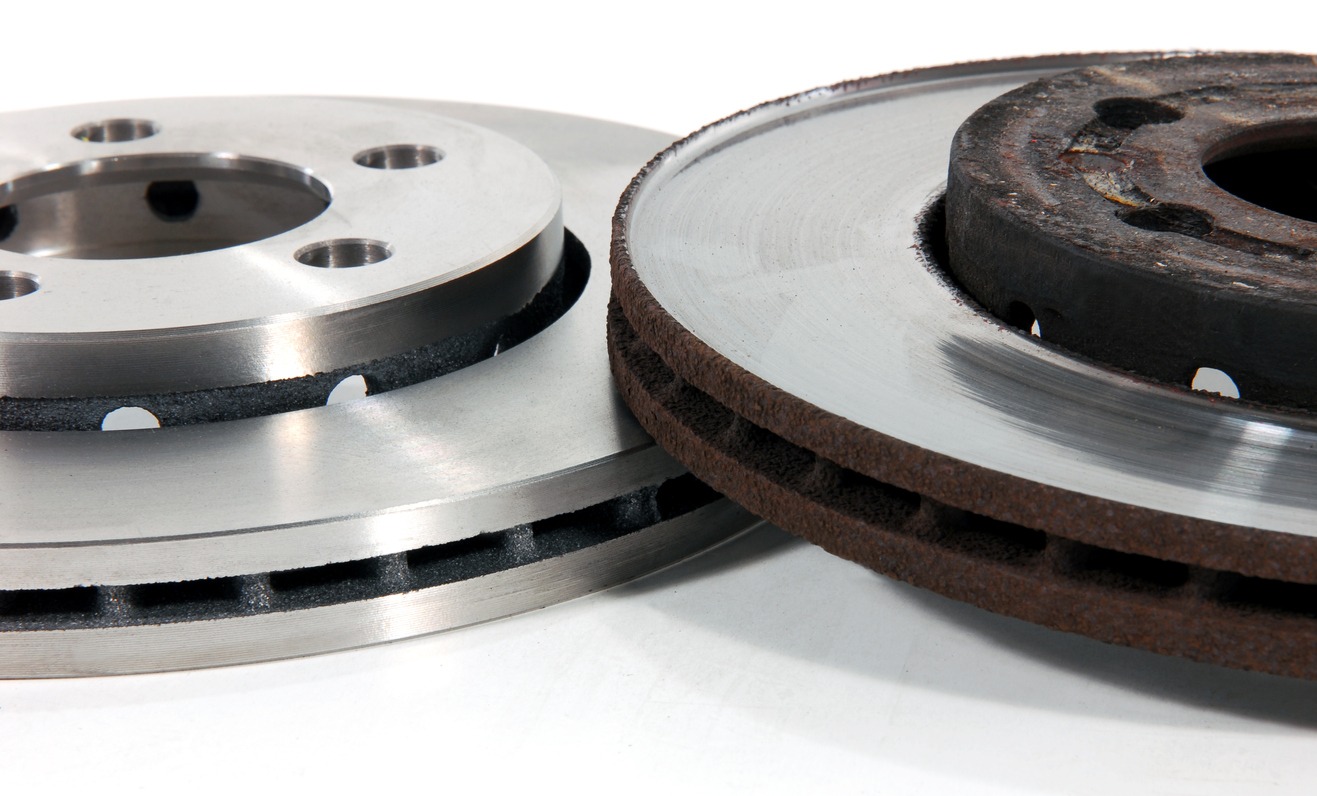

Signs of Brake Rotor Wear and Tear

Regularly monitoring the condition of your brake rotors is crucial for maintaining optimal braking performance and ensuring your safety on the road. Here are some common indicators that your brake rotors may need attention or replacement:

- Visible grooves or scoring: One of the most obvious signs of wear is the presence of deep grooves or scoring marks on the rotor surface. Over time, as brake pads press against the rotors, they can wear down the metal, leading to these visible grooves. If the grooves are deep enough, it can significantly diminish the rotor’s effectiveness and may require replacement.

- Vibrations during braking: If you feel vibrations or pulsating sensations through the brake pedal or steering wheel during braking, it could indicate that your rotors are warped. Warping occurs due to uneven heating and cooling of the rotor surface, often caused by excessive or harsh braking. This uneven surface interferes with the smooth operation of the brake pads, leading to vibrations.

- Excessive rotor thickness variation: Rotors can wear unevenly, leading to variations in thickness. This condition, often called “rotor runout,” can cause brake pedal pulsation similar to warping. Measuring rotor thickness in multiple spots can reveal if there’s significant variation, indicating the need for rotor machining or replacement.

- Rust and corrosion: While some amount of rust on rotors is normal, especially after rain or in humid conditions, excessive rust can be problematic. Severe rusting, especially on the braking surface, can reduce the effectiveness of the brakes and may lead to rotor replacement.

- Strange noises during braking: Unusual noises such as grinding, squealing, or scraping sounds during braking can be a sign of rotor problems. These sounds may indicate that the brake pads are worn down to the point where metal components are contacting the rotor surface, potentially damaging the rotor.

- Excessive heat damage: If a rotor has been exposed to excessive heat (due to hard braking, for instance), it may show signs of heat damage, such as bluish discoloration or cracks. Heat-damaged rotors can be weaker and less reliable, necessitating replacement.

- Brake pad impressions: Sometimes, brake pads can leave material deposited on the rotor surface, creating uneven spots. These pad impressions can cause braking issues similar to those caused by warped rotors.

If you notice any of these signs, it’s essential to have your brake system inspected by a professional. Depending on the severity of the wear and tear, your rotors may need to be resurfaced or replaced to maintain your vehicle’s braking performance and safety.

Maintaining Brake Rotors

Proper maintenance of brake rotors is essential for ensuring their longevity and maintaining optimal performance. Here’s a guide on how to maintain your vehicle’s brake rotors:

1. Have it inspected regularly

It is advisable to inspect your brake rotors at least twice a year, typically during tire rotation or when you have your brakes serviced. However, more frequent checks might be necessary if you frequently drive in harsh conditions. These are the key aspects to inspect:

- Thickness: Measure the thickness of the rotor to ensure it meets the minimum specification set by the vehicle manufacturer.

- Surface condition: Look for any signs of uneven wear, deep grooves, or scoring.

- Warpage or distortion: Check for any warping or heat spots that could indicate overheating or uneven braking.

- Rust and corrosion: Examine for excessive rust, especially on the rotor’s surface, which can affect braking performance.

2. Perform regular cleaning and rust prevention

Keeping your vehicle’s brakes in top shape involves more than just looking after the brake pads. The brake rotors also need some TLC to ensure they perform at their best.

Brake rotors can accumulate dirt and debris, which affects braking. Regularly clean them with a brake cleaner spray to keep them in good condition. Just spray on and wipe off with a clean cloth. Use a wire brush to gently scrub away surface rust and debris, particularly after exposure to moisture or salt. Also, be careful to avoid getting oils, grease, or other contaminants on the rotor surface during maintenance or repairs.

Since brake rotors can rust, causing uneven surfaces and noise, it’s smart to use an anti-rust spray. Parking in a dry garage or covering your vehicle when outside helps, too.

3. Follow preventative measures

To make your brake rotors last, follow these tips:

- Try not to brake hard frequently. This practice can cause rotors to overheat and warp, leading to uneven wear. Instead, brake gradually to reduce heat and prolong rotor life.

- Use high-quality brake pads. Investing in quality brake pads is key. They withstand high temperatures better, reduce stress on your rotors, and improve your vehicle’s braking performance.

- Stay alert on the road. Being attentive helps you avoid sudden stops, reducing wear and tear on your rotors.

- Regularly check brake fluid. Ensure your brake fluid is at the right level and change it according to the manufacturer’s recommendations.

4. Know when to replace your brake rotors

It’s time to think about replacing your rotors when they show signs of wear, much like you would with your brake pads. In fact, with newer vehicle models, rotors may need to be replaced as often as the brake pads. For the best braking performance and safety, it’s a good idea to replace them together with your brake pads.

Always follow the vehicle manufacturer’s guidelines for rotor replacement. Replace the rotor if it has worn down to the minimum thickness specification.

Gone are the days when brake rotors would outlast two or three sets of brake pads. Nowadays, they might wear out just as fast as the pads themselves. Also, if a rotor is excessively warped, cracked, or has deep grooves, it should be replaced. If you experience persistent braking problems despite maintenance, it might also be a sign to replace the rotors.

Remember, each time you use your brakes, both the pads and rotors wear down a bit. On average, rotors tend to last between 30,000 and 80,000 miles, but this can vary depending on your driving habits and conditions.

Choosing the Right Brake Rotors for Your Vehicle

Selecting the appropriate brake rotors for your vehicle is a critical decision that can significantly impact your driving experience and safety. Here are some key factors to consider when choosing brake rotors:

1. Vehicle type

For standard passenger vehicles, blank and smooth rotors are typically sufficient. They offer a good balance of performance, durability, and cost-effectiveness for everyday driving.

If you own a performance or sports car, consider drilled or slotted rotors or a combination of both. These provide better heat dissipation and improved braking performance, which is crucial for high-speed driving.

Meanwhile, slotted rotors are often recommended for vehicles that carry heavy loads or are used for towing. Their design helps maintain braking performance under the strain of the additional weight.

2. Driving habits

If most of your driving is in urban areas with frequent stops, drilled rotors can be beneficial due to their better heat dissipation properties. If you drive primarily on the highways, blank rotors might be sufficient, as they are less prone to warping under less frequent braking.

For drivers with a more aggressive style, such as frequent rapid acceleration and braking, slotted or drilled and slotted rotors may be more appropriate. They provide better performance under these high-stress conditions.

3. Environmental conditions

In areas with frequent rain, drilled rotors can offer an advantage as the holes allow water to be expelled from the rotor surface more efficiently, improving wet-weather braking.

For driving in mountainous or hilly areas, where brakes are used more intensely, rotors that excel in heat dissipation (like drilled and/or slotted rotors) are preferable to prevent brake fade.

4. Budget and longevity considerations

Blank and smooth rotors are generally more affordable and offer a good lifespan, making them a cost-effective choice for most drivers.

Higher-performance rotors, like drilled and slotted ones, may wear out quicker than blank rotors, especially under harsh driving conditions. Consider the balance between performance needs and replacement costs.

5. Compatibility with brake pads

Ensure that the chosen rotors are compatible with your brake pads. Some high-performance rotors may require specific types of pads to function optimally.

6. Manufacturer recommendations

Always consider the manufacturer’s recommendations for your specific vehicle model. Some vehicles may have specific requirements or limitations when it comes to brake rotor upgrades.