Introduction

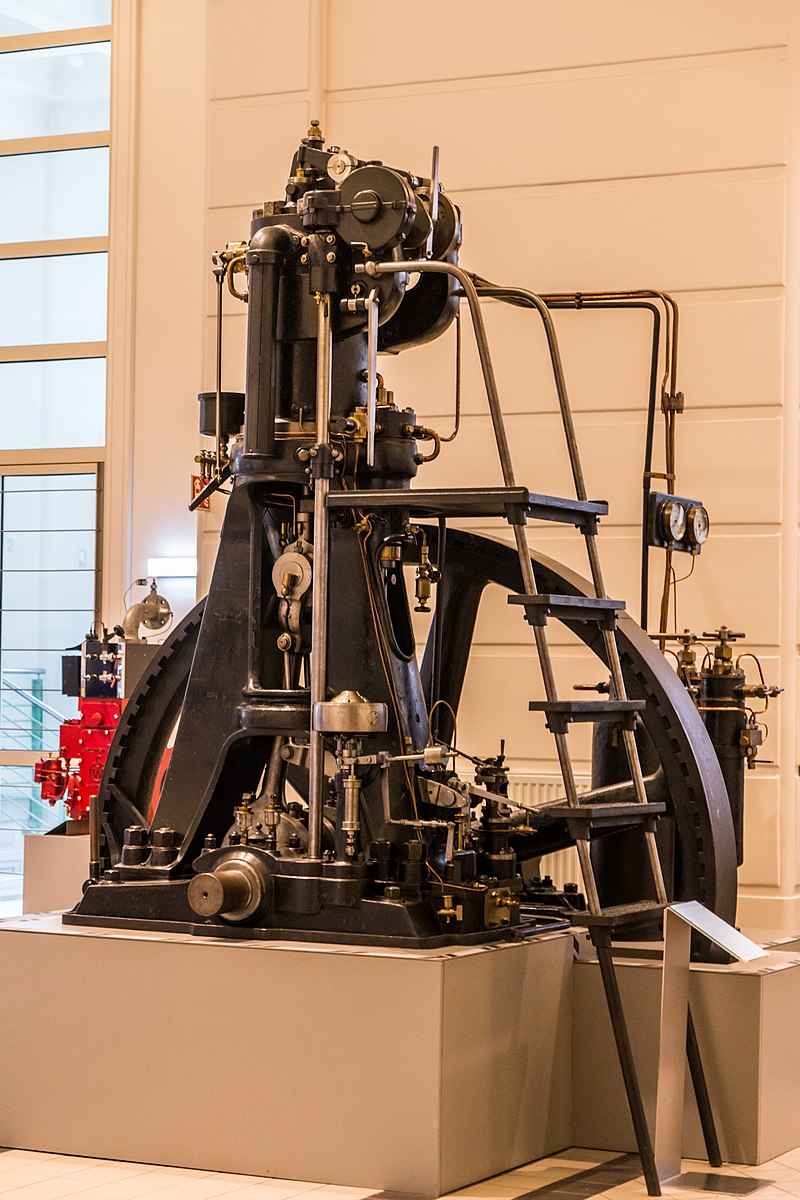

In the realm of internal combustion engines, few innovations have stood the test of time and technology quite like the diesel engine. The diesel engine has played a pivotal role in revolutionizing transportation, industry, and even power generation since its inception in the late 19th century.

Its efficiency, durability, and torque-rich performance have made it a cornerstone of modern machinery, propelling everything from cars and trucks to ships and generators. At its core, a diesel engine operates on the principle of compression ignition, distinguishing it from its gasoline-powered counterparts.

This means that instead of relying on a spark to ignite the air-fuel mixture, diesel engines compress air to a high enough temperature and pressure that it ignites the diesel fuel sprayed into the combustion chamber. This fundamental difference gives diesel engines their characteristic efficiency, as they extract more energy from the same volume of fuel compared to gasoline engines.

Know more about the Diesel Engine

One of the hallmarks of diesel engines is their unparalleled torque output, making them particularly well-suited for tasks that demand heavy lifting or high towing capacity. This trait has made them the workhorse of industries ranging from freight transportation to construction. Moreover, the durability of diesel engines is legendary; they are known for their longevity and ability to withstand harsh operating conditions, making them the backbone of fleets that traverse long distances or endure rugged terrain.

As environmental concerns take center stage, diesel engines have also evolved to address emissions and efficiency challenges. Advancements in technology have led to the development of cleaner-burning diesel engines, incorporating sophisticated emission control systems and, in some cases, alternative fuels. This ongoing evolution underscores the adaptability and resilience of this venerable power source.

The two types of Diesel Engine

Known for their reliability, durability, and fuel efficiency, diesel engines are commonly used in trucks, buses, ships, construction equipment, and even in some passenger cars. These engines are divided into two primary categories: two-stroke and four-stroke diesel engines. In this article, we will explore the differences between these two types of diesel engines, their advantages, and their applications.

Two-Stroke Diesel Engines

Two-stroke diesel engines are a traditional and less common type of diesel engine. They have a unique operating cycle that involves two strokes of the piston to complete one power cycle. Here are some key characteristics of two-stroke diesel engines:

- Simplicity: Two-stroke diesel engines are known for their simplicity in design. They have fewer moving parts and require less maintenance, making them attractive for certain applications.

- High Power-to-Weight Ratio: These engines are typically more compact and lightweight compared to their four-stroke counterparts, making them suitable for applications where space and weight constraints are important.

- Less Efficient: Two-stroke diesel engines are generally less fuel-efficient and emit more pollutants than four-stroke engines. This has led to their decline in popularity in recent years, especially in applications requiring compliance with stricter emissions regulations.

- Limited Applications: Two-stroke diesel engines are commonly used in smaller vessels, such as fishing boats and some older ship engines, as well as in industrial and stationary power generation applications.

- High Power Density: Two-stroke engines can achieve higher power density, meaning they can deliver more power per unit of engine size compared to four-stroke engines. This is advantageous in applications where space is limited.

- Less Maintenance: Due to their simpler design, two-stroke engines may require less maintenance and have fewer components that can fail.

- Less Valve Mechanism: Since two-stroke engines do not have valves, there is no need for a complex valve train, which can reduce maintenance and potential points of failure.

Applications

- Marine Propulsion- two-stroke diesel engines are commonly used in large marine vessels due to their high power-to-weight ratio and efficiency at high RPMs.

- Small Power Equipment-they find applications in small power tools and equipment, such as chainsaws and motorcycles, where simplicity and weight considerations are paramount.

Four-Stroke Diesel Engines

Four-stroke diesel engines are the most common type of diesel engine found in various vehicles and industrial equipment. They operate on a standard four-stroke cycle, which includes intake, compression, power, and exhaust strokes. Here are the key features of four-stroke diesel engines

- Efficiency: Four-stroke diesel engines are known for their superior fuel efficiency, thanks to their well-designed combustion process. They generate more power from a given amount of fuel and produce fewer emissions compared to two-stroke engines.

- Widespread Use: These engines are widely used in a broad range of applications, including passenger cars, trucks, buses, construction equipment, power generators, locomotives, and large ships. Their versatility and efficiency make them a popular choice in the industry.

- Compliance with Emissions Regulations: Four-stroke diesel engines can be equipped with advanced emissions control technologies to meet stringent environmental standards, making them a preferred choice for applications requiring clean and sustainable operation.

- Durability: Four-stroke diesel engines are built to withstand heavy-duty use, making them a reliable choice for long-term performance in demanding environments.

- Torque: Diesel engines produce a high amount of torque at low RPM, making them well-suited for applications where high torque is needed, such as in trucks and heavy machinery.

- Longevity: With proper maintenance, diesel engines can have a longer lifespan than gasoline engines, which can be an advantage in commercial and industrial settings.

Applications

- Automotive Industry- most cars, trucks, and SUVs on the road today are powered by four-stroke diesel engines, thanks to their balance of power, efficiency, and emissions control.

- Industrial Machinery- four-stroke engines are widely used in various industrial applications, including generators, construction equipment, and agricultural machinery, where reliability and fuel efficiency are paramount.

Conclusion

In conclusion, diesel engines come in two primary types: two-stroke and four-stroke. While two-stroke engines offer simplicity and a high power-to-weight ratio, they are less fuel-efficient and less environmentally friendly, limiting their use in modern applications. On the other hand, four-stroke diesel engines are renowned for their efficiency, widespread use, compliance with emissions regulations, and durability, making them the preferred choice for a broad spectrum of vehicles and equipment.

The choice between the two types of diesel engines largely depends on the specific requirements of the application, with four-stroke engines being the go-to option for most modern diesel-powered machinery and vehicles.

As technology advances, the distinction between these two types may continue to evolve, but their fundamental differences and characteristics will remain integral to the diesel engine landscape. Understanding the distinctions between these engine types is essential for selecting the most suitable option for a given application, ensuring optimal performance and efficiency.