The suspension system is arguably one of the most complex sections of a vehicle, as it consists of multiple components that work together to provide the driver and passengers with a more comfortable ride. The shock absorber is a component of the suspension system that will be discussed in this article. It is designed to mitigate the impact that the wheels receive from the ground, thereby preventing the driver and passengers inside the vehicle from feeling the impact. Learn more about car shock absorbers and their significance by reading the text below.

Components of a Shock Absorber

Mount

Mounts for shock absorbers are components that secure shocks to the vehicle’s frame and suspension. There is an upper mount and a lower mount. Both of these may have a “eye” into which a bushing and fastener can be inserted.

Bushing

On the mountings is the bush, which is typically composed of rubber or urethane. This bushing absorbs vibrations and is constructed with distinct metal components to prevent noise and wear. Bushings are among the replaceable shock absorber components.

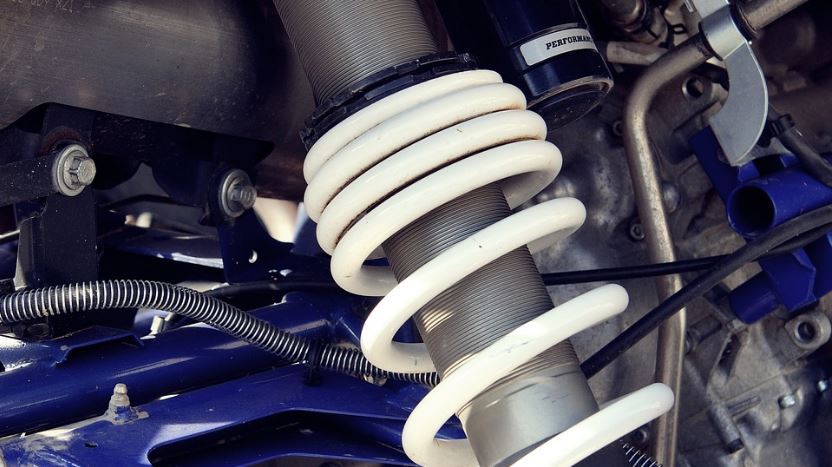

Coil Spring

Certain types of shock absorbers incorporate a coil spring into the shock absorber assembly. These are commonly referred to as coil-over or spring coil shock absorbers.

Piston and Piston rod

The piston of the shock absorber contains apertures or openings. The operation of the shock is dependent on the flow of oil through these conduits.

Cylinder

This cylindrical tube serves as the shock absorber’s main bulk. It comprises of compression oil and a moving piston within.

Bolts/Fasteners

The fasteners that secure the shock to the vehicle’s body on one end and the suspension on the other. These must be tightened with the appropriate torque values. Under-torqueing can result in shocks that are loose and do not function as anticipated.

Oil

The oil seal prevents oil from seeping out of the shock absorber tube during operation. Additionally, it prevents contaminants from penetrating the tube. The oil guide is an oil passage that facilitates the efficient operation of the absorber.

How a Shock Absorber Works

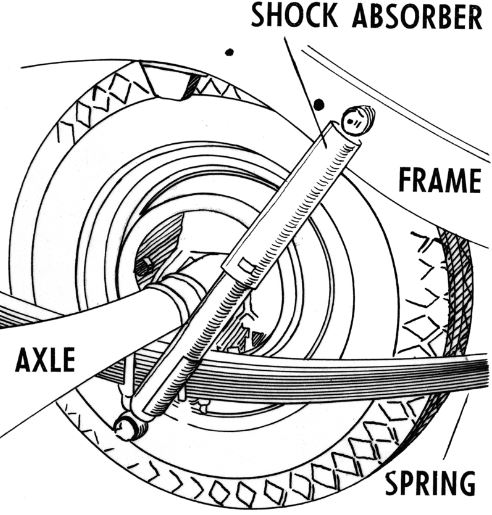

A vehicle’s suspension system is located between the frame and the road. The primary purpose of a vehicle’s suspension system is to optimize its overall performance on the road. Additionally, the suspension system serves to absorb road imperfections and provide a safe and comfortable ride.

Not only does the suspension system maintain the wheels in contact with the ground, but it also performs a number of other crucial functions, such as controlling the nose-dive during braking. As weight shifts forward due to momentum during deceleration, the suspension assists in resisting and balancing this shift.

A body would lean away from the direction of travel if left unchecked. This transfers weight and diminishes traction. The suspension system aids in body support and rolling resistance. Under acceleration, the front end of a powerful race car will become lighter and raise, which is essentially the antithesis of nose-diving. The shocks will assist in opposing this force.

Several factors can lead to a loss of traction, but on a bumpy road, the suspension forces the tires to make contact with the ground, thereby increasing adhesion. On vehicles with low ride height, the car’s body or chassis may scrape or bottom out when it comes into contact with the track. The suspension will assist in preventing this.

The shock absorbers, also known as shocks or dampers, support the coil spring to reduce the impact of a jolt or pothole further. Our vehicle vibrates when it encounters an uneven surface. A moving object will continue to move in accordance with Newton’s first law unless an external force acts to stop it. If nothing interferes, he is implying that our car will continue to bounce.

Ideally, there should be no disturbance in our vehicle. In other words, we do not want the red line to rise or fall; we want it to remain level at zero. Here, shock absorbers come into play. Every time the vehicle is jostled, the impact is transferred through the tires and into the suspension system.

As the car’s suspension moves up and down, the shock absorbers gradually dampen the vibrations until we no longer sense them. The orifices are extremely small and only permit a minute quantity of fluid to pass through. This opposes the descending force. At this juncture, the kinetic energy is converted into thermal energy, reducing the car’s vibrations.

The shock absorbers work to decelerate and reduce the magnitude of the bouncing motion by converting the kinetic energy into heat energy that can be dissipated through the absorber assembly’s hydraulic fluid. This conversion of energy provides a more stable ride and helps maintain the tires in contact with the road by preventing excessive body bouncing.

Because the water resists and restricts your movement while swimming, you move much more slowly in water than on land. This is the basis for how impact absorbers function. Within the shock absorber is a piston that travels within a hydraulic fluid-filled tube. As the piston presses into the tube, it forces fluid out through tiny holes and valves, thereby regulating the amount of movement resistance.

Types of Shock Absorbers

There are numerous types of shocks, and each vehicle type requires a specific model, but all shock absorbers fall into one of three categories:

1. Telescopic Shock Absorber

Telescopic shocks, a simple form of shock absorber, are commonly used for the front suspension of motorcycles. They are subdivided into bi-tube and mono-tube dampers, which can be compressed and extended. They are available in a range of sizes, require minimal upkeep, and are reasonably priced.

2. Strut Type Shock Absorber

Although they perform the same fundamental function, struts replace a portion of the suspension system and must be constructed to withstand greater loads and forces. Larger automobiles are increasingly adopting strut-based suspension design, which is most frequently observed on the front and rear of small to medium vehicles. The category of struts is subdivided further into sealed and repairable elements.

Hermetic units, as their name suggests, are meant to be totally replaced, whereas repairable struts can be fitted with replacement strut cartridges. Hermetic units are intended to be completely replaced.

3. Spring Seat Shock Absorber

The spring seat type resembles both telescopic and strut types of shock absorbers. Similar to struts, a spring seat shock combines the functions of a suspension unit and a dampening mechanism into a single housing unit. However, unlike struts, they are not designed to withstand significant side loads. Spring seat shocks are constructed with the same components as conventional shock absorbers and are also sealed, necessitating replacement.

To summarize

A shock absorber is essentially an oil pump, a device used to absorb and redistribute as kinetic energy any abrupt or violent thrust or shake. Shock absorbers are essential for motorcycle and automobile suspension, whereas landing gear is a component of industrial machine support systems. Typically, a shock absorber is a cylinder with a movable piston cushioned by hydraulic fluid or air.

Technically and conceptually, shock absorbers underwent significant advancements throughout the 20th century. In spite of this, the production and utilization of automobiles need the introduction of a new generation of shock absorbers at each and every juncture and benchmark in the automotive industry. Therefore, the 21st century has witnessed more advanced ideas and designs for automobile shock absorbers.