Cars are engineering marvels with many different complex components working in synchronization to deliver the performance that you require. Because of the increasingly rapid change in technology and complexity, most of the drivers are not aware about their car’s major components. But given the fact that millions of drivers are rescued by AAA in the United States every year, it is important that you at least understand the major components of your car so that you can help yourself when times call for it and not get defrauded by mechanics.

In this article, we are going to cover some of the major car components with significant detail but with easy-to-understand language. We will discuss about the brakes, engine, transmission, AC system, radiators, and many other basic and major components. After reading this article, you are sure to come out well-informed about your car’s basic parts and potentially begin your journey towards becoming a gearhead. To learn more about cars, trucks, and RVs, visit Cargister.

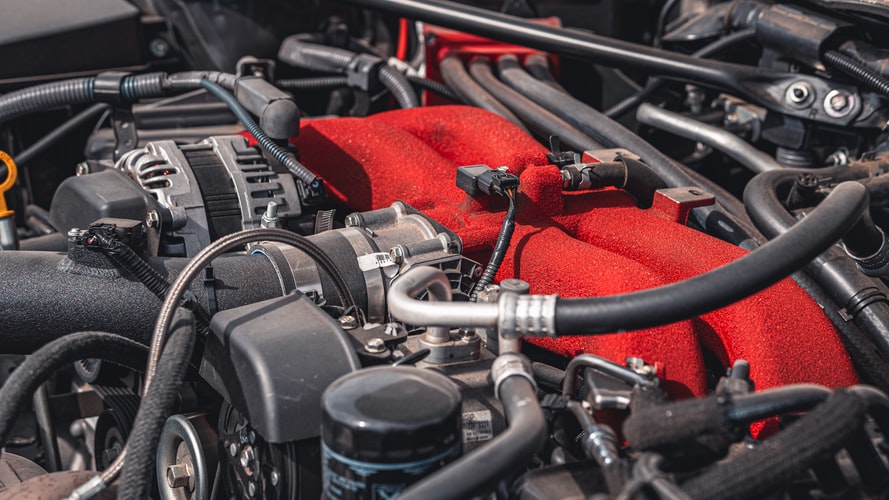

The Engine

A car’s engine is the most important and the major component out of all, it is imperative that on your journey to become a gearhead, you understand the basic functioning of the engine. There are two types of engines that are widely used: the internal combustion engine (ICE) and the external combustion engine (ECE).

An internal combustion engine is an engine where the combustion process of the fuel i.e., fuel and air combust inside the engine, in a combustion chamber. This high temperature and high gas pressures by the combustion produces energy, which is directly applied on the pistons, and therefore, resulting in mechanical work and thus moving the car.

Whereas, in an external combustion engine, the combustion process happens outside the engine and the heated fluid inside acts on the components of the engine and produces motion. Steam engines are prime examples of an ECE engine where the coal i.e., the fuel is burned outside the engine.

In 1864, Nicolaus August Otto designed an ICE engine which is called as four-stroke engine now. It this basic design that we still use today in cars around the world.

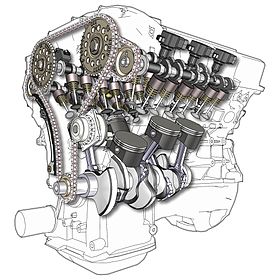

There are many different parts of an engine. Let’s explore the major parts of a four-stroke V6 engine so you can understand the basic working principle of your car’s engine and diagnose any potential issues.

Engine Block

This is most important part of an internal combustion engine; it can be said it is the foundation of an engine. Made mostly from aluminum alloy or sometimes gray cast iron, it is where the cylinders and other parts are housed which are the big tubes casted into the overall structure, more cylinders mean more power. This is where the engine’s pistons move vertically and produce motion, the engine block also releases the heat produced by the friction into the atmosphere and the engine coolant.

This is where the V6 and V8 engine names come in. An engine with 6 cylinders is called V6 whereas an engine with 8 cylinders is called a V8. The letter ‘V’ is because of the engine’s appearance as more than 4 cylinders divide the cylinder banks into two with the crankshaft going through the middle of them.

Combustion Chamber

This is the powerhouse of the engine and is where the fuel, pressure, air, and electricity interact to ignite i.e., combust that sets the pistons into vertical motion and ultimately moving the car. The cylinders, pistons, and the cylinder head are all housed in this combustion chamber where each play their own important role. The cylinders are the wall of the combustion chamber, the pistons are the bottom, and the cylinder head are the top of the combustion chamber.

Cylinder Head

The Cylinder Head is another very crucial part of the engine, it is set above the cylinders on the top of the engine block and has the majority of the components of an engine attached to it. The main purpose of the cylinder is to shut the combustion chamber from the top, the remaining gap between the two is sealed by the head gasket.

Pistons

Pistons are key parts of an engine which convert the combustion into mechanical work. The pistons move in a vertical motion where the expanding gases produced by the combustion move the pistons downwards which then turns the crankshaft, and consequently, through a system of gears, this energy is converted into motion and the car moves. The pistons are attached to the crankshaft through a connecting road, also known as the con rod.

Crankshaft

The crankshaft is an internal combustion engine’s backbone. The linear motion produced by the piston’s vertical movement into rotational motion which allows the car to move and drive. As mentioned above, the pistons are connected to the crankshaft through a connecting rod and the crankshaft, itself, is attached to the engine block.

Camshaft

Camshafts are another very crucial part of the engine and can be called the brain of an internal combustion engine. The purpose of the camshaft is open and close the intake & exhaust valves at the right time to ensure that the engine is running optimally. It is found on top of the engine block and above the crankshaft. The number of camshafts depends on the number of cylinders banks; in a V-shaped engine would have two separate camshafts would be used. The camshaft is connected to the crankshaft through a belt, gears, or a chain.

Valves

An internal combustion engine has two valves: intake and outtake vales. An intake valve is in the cylinder head which opens at the right time in synchronization in order to let in fuel and air into the combustion to allow a small explosion to happen. Whereas an outtake valve–as the name implies–opens following a combustion to let out the exhaust out of the combustion chamber.

Fuel Injectors

For the combustion to happen to move the pistons which move the crankshaft and get the car moving, fuel is required in the cylinders. There are three fuel injection systems used by cars all around the world: the direct fuel injection system, ported fuel injection system, and lastly, the throttle body fuel injection system.

In the direct fuel injection system, each cylinder will have its own injector which spray the fuel directly into the combustion chamber with proper timing in the cycle in order to allow the combustion process to happen.

In the ported fuel injection system, the injectors sprays fuel into the intake valves which mixes with the air. When these valves open, the fuel-air mixture is taken into the engine cylinder and allowing a combustion. The fuel injectors in this system are fixated in the runners of the intake manifold.

In the throttle body fuel injection system, the injectors are attached to the throttle body where the fuel is sprayed above the throttle plates where it mixes with air and is taken into the cylinders by the intake valves.

The fuel sprayed has different types for different types of cars as well. It is important you are also aware about this.

Spark Plugs

As the name of this part implies, it initiates the combustion process by igniting the fuel and air mixture which leads to a small explosion and consequently moving the piston downwards to turn the crankshaft. It initiates the entire combustion process and is a crucial part of the engine.

You can find more about the components of a gasoline-powered engine in detail here.

The Brakes

Brakes are one of the most crucial components of a car. It is one of those major components that is taken for granted by drivers; however, it is important that you are aware about the basic working principles so that you can avoid an impending disaster—a matter of life and death. The modern braking system has come a long way and has a long history.

Brake Parts

In this part of the car braking system section, we will discuss about the different parts that are in a modern car’s braking system and how each is interrelated. A traditional braking system will have three major parts: the brake disk or rotor, the brake caliper, and the brake pads.

Brake Rotor

Brake rotors are circular metal discs attached to a wheel, a car would have four brake rotos attached to four wheels—two in the front and two in the back. The main purpose of the brake rotor is to decelerate the car by slowing down the rotations of the wheels by using friction provided by the other brake components. Without brake rotors, it is not possible to slow your car down as the other components work together to bring a car to a stop.

Because the brake rotors are exposed to extreme conditions such as heat, road debris, rainy or snowy conditions, dust, and other external elements, it is very imperative that the brake rotors can withstand such harsh conditions. This means that it is important you invest in good quality brake rotors that can go through these exacting situations and are also able to last.

Therefore, you must regularly get your brake rotors inspected and replaced to keep your braking system efficient and effective.

Brake Caliper

The brake calipers can perhaps be called the heart and soul of the entire braking system because they allow the braking to actually happen. It is a clamp-like component that partially covers the brake rotors. It pushes the brake pads onto the brake rotor when you depress the brake pedal. The brake caliper is a hydraulic actuator as it uses brake fluid to cause motion.

Brake Pads

The brake pads are another very important component of the system. These are the parts that directly get into contact with the brake rotors and are moved by the brake calipers towards the brake rotors and convert the kinetic energy into thermal energy. And, as such, these parts receive the most wear and tear because of the friction and the amount of heat. Consequently, it is very crucial that you also inspect this part frequently to allow for safe and effective braking.

Brake pads are made from different materials, suitable for different uses and conditions and they also come in different qualities. Therefore, you must choose brake pads that are the most suitable for your use and conditions.

Brake lines

As the name implies, these are the lines that supply the hydraulic fluid i.e., the brake fluid to the brake caliper so that it can push the brake pads onto the brake rotor in order to bring your car to a halt. It is another very vital part of the overall braking system in a modern car. However, it is also prone to many issues and can go unnoticed such as leakages and this can be a major safety issue, potentially can cause a car accident if the vehicle is unable to stop due to a lack of hydraulic fluid.

Overall functioning of the braking system

As you may have now realized, the overall functioning of the braking system is a synchronized functioning of all the different brake parts. As you press down the brake pedal, the master cylinder pushes the brake fluid to the calipers which then force the brake pads down onto brake rotors which are attached to the wheel. This produced friction and heat, which converts the kinetic energy of the car into thermal energy which leads to the car decelerating and ultimately coming to a stop.

Transmission System

Transmission system is one of another vital major components of a car. The transmission is simply a car’s gearbox which is, in principle, similar to a bicycle’s gears system. Modern cars come with two types of transmissions: manual or automatic. We will explore each system briefly.

Fundamental Working Principle of a Transmission System

Whether your car is an automatic or manual transmission, the fundamental working principle of the overall system is the same. The primary difference between the two types is that the driver must engage the clutch to disconnect the engine and the transmission to change the gear whereas in an automatic transmission car, this happens automatically.

The gear lever moves the gears to connect with the other one. This gear lever is controlled by the driver by the clutch pedal (if manual system) and if it is automatic then this process is done automatically. The gear level then moves the clutch plate or the collar plates into place to move up to higher gears which are connected to your car’s differential. As the gear level moves, higher/lower gears are connected at different times. As such, this determines which gears turn and what power ratio is supplied from the engine to the wheels.

Manual Transmission: the gear ratios are shifted manually in the power train which then alters the engine speed and the road speed. As you depress the clutch, the clutch plates or the collar plates disconnect and moves onto a gear selected. This is the reason you may feel a jerk when you change a gear in a manual transmission. Manual transmission comes in different types including the dual-clutch, unsynchronized, constant mesh, automated, single clutch, and preselector types.

Automatic Transmission: in this system, the clutch is automatic. The car’s sensors, processors, and other components engage the clutch at the right moment and change into a higher gear as soon as it is needed depending on the speed, accelerator position, and other aspects such as the car’s driving modes (Eco, Sports, etc). The gears are changed relying on the torque converter rather than human input. It comes with different types including AMT, CVT, DCT, and Torque Converters.

Overall, the transmission system of a modern car is very complex, and it would take an entire book to completely analyze and understand each single part of the transmission system. It is also a part that comes up with many problems and you should be able to recognize the signs of this happening to avoid further damage to your car. We have kept it brief and simple so that a person without much background information can understand the fundamental working principle of the transmission system.

Air Conditioning System

The air conditioning system is a mystery for many drivers as simply pressing the AC button blasts the driver with cold air rushing in from the air vents. In this section, we will cover how the AC system works in a car and the components used in it.

The fundamental working principle of an AC system is that it cycles the refrigerant gas which changes the gas into liquid state, and it cycles continuously. As the cycle ends, the refrigerant is in a cold gaseous state and in the evaporator. As air is blown on it, it cools down which is then delivered to the car’s cabin providing you with the cold air out of the air vents.

The AC Components

High-pressure side

Compressor: an AC compressor works by a pulley which is connected through a belt to the crankshaft. The pistons inside are then powered which intake low-pressure and low-temperature gas and convert it into high-pressure and high-temperature gas by compressing it.

Condenser: the refrigerant reaches the condenser after going through the compressor, at this point it maintains a high pressure due to the compression by the compressor. The purpose of the condenser is to remove this heat out of the system. It makes the refrigerant cooler, turning it into a high-pressure liquid and cooler temperature form.

Dryer: the dryer’s purpose is to intake the liquid from the condenser and moves it through different filters and desiccants. This will absorb water, remove any debris, or harmful particles. The moisture is removed by the desiccants, and it is important this is done so that the refrigerant does not freeze as it goes into an expansion valve because it is already cold enough.

The low-pressure side begins with the expansion valve.

Expansion Valve: the expansion valve will basically control the level of refrigerant that is allowed to go through the AC system. The dryer’s outtake valve opens, and the expansion valve takes in the refrigerant, it cools the refrigerant even further and reduces the pressure.

Evaporator: the evaporator takes in the low-pressure and low-temperature refrigerant from the expansion valve and absorbs the heat which puts the temperature of the refrigerant to 32 degrees. At this temperature, the refrigerant—instead of freezing, boils—therefore, it turns back into a gaseous state which absorbs even more heat. This gas goes back to the compressor and the entire process runs in a cycle.

The cold air enters the cabin as the fan blows outside-temperature air onto the evaporator and the air cools due to the low-temperature and then this air enters the cabin of your car as cool AC air.

Suspension System

The suspension system is another very important part of a modern car, for comfort but also for safety. Let’s explore the anatomy of the suspension system of a car briefly.

The main parts of a suspension system are the springs and the shock absorbers.

Springs: most modern cars use a spring coil per wheel. However, older vehicles or a pick-up truck will use leaf springs which look like narrow metal stacked on top of each other. Some cars also use a torsion bar which is not spring, rather it’s a piece of metal that is connected at one end of the car and to the entire suspension system. T

The primary purpose of springs is to absorb the energy when a car hits bumps or uneven surfaces which provide comfort to the driver and the passenger because it dampens the effects of a bumpy surface. In addition, the springs ensure that the car stays in contact with the road and compensates the centrifugal forces a car faces when turning a car, helping to avoid a roll over as well.

Shock Absorbers: shock absorbers’ purpose is to release the energy from the springs in a fashion that is safe and comfortable for the car users. The springs absorb the energy; however, they cannot release energy in a way that is comfortable or safe which will cause the car to bounce and rebound which makes it very unsafe and uncomfortable.

The suspension systems of cars are becoming more advanced day by day. More expensive and luxury cars have air suspension which use microprocessors to move the air spring up and down and air is added or removed to maintain a certain level of comfort in all situations including a sharp corner.

Conclusions

Cars are a complex system of components and parts that work in synchronization to serve the purpose. However, sometimes things do go north, and it is important that, at these times, you are well-aware about the basic and major components of a car and their working principles so that you can come to your own rescue or avoid any dubious mechanics who only aim to defraud their clients, using the client’s lack of information as leverage.